The key role of DFM optimization in the manufacturing

August 8, 2025 • by [email protected]

Every year, countless CNC projects fail—not because of bad ideas, but due to small design errors that block production or cause defects. This problem wastes money and delays entire supply chains. For over 20 years, I have helped global customers bridge the gap between creative design and smooth manufacturing. The secret? DFM (Design for Manufacturability) optimization. In this guide, I’ll show you exactly how DFM transforms your digital model into a finished metal CNC part, ready for market.

DFM connects the worlds of engineering and manufacturing. It helps you avoid cost overruns, missed deadlines, and frustrating rework. With a solid DFM process and a partner like Prime, your design gets produced right the first time.

Too many companies focus on beautiful CAD drawings and leave manufacturability for later. If you want to avoid common pitfalls and ensure every order arrives on time and as specified, DFM is the answer.

Why Does DFM Matter in CNC Part Production?

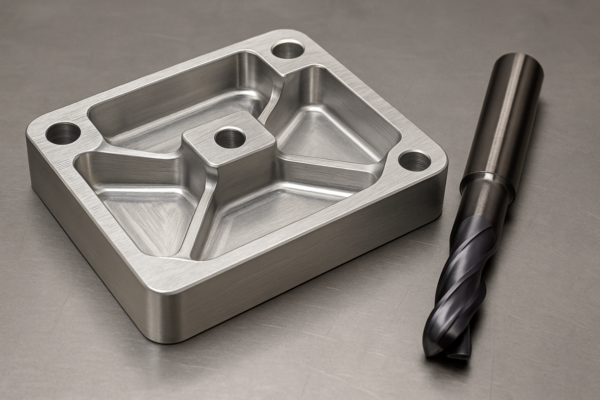

Even the best 3D model is only as good as its ability to be manufactured. I have seen well-intentioned engineers submit designs with tight corners, deep cavities, or impossible tolerances—features that seem minor on screen but cripple efficiency on the shop floor.

DFM makes the difference between fast, cost-effective CNC parts and repeated failures. When DFM is applied, every feature serves a purpose and every detail aligns with manufacturing reality.

DFM Solves Hidden Manufacturing Challenges

Consider these common pain points that global buyers face:

- Parts that cannot be machined without special, costly tools.

- Tolerances so tight they require multiple reworks.

- Surfaces specified at a finish far beyond functional needs.

- Features impossible to reach without complex multi-axis machining.

By using DFM, you can avoid:

- Excessive material waste.

- Unexpected tool breakage.

- Last-minute drawing changes and clarifications.

- Delayed shipments and missed selling seasons.

Table: CNC Part Challenges and DFM Solutions

| CNC Challenge | DFM Optimization Outcome |

|---|---|

| Sharp internal corners | Use of tool-compatible fillets |

| Unnecessarily deep pockets | Revised geometry for rigidity |

| Mixed unit systems | Standardized to metric/imperial |

| Overly tight tolerances | Prioritization of critical dimensions |

| Undefined datum references | Clear, unified reference points |

How Prime’s DFM Process Transforms Your CNC Projects

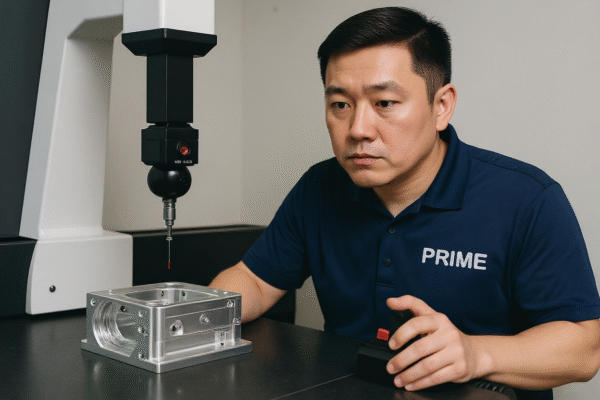

At Prime, DFM is not an optional “add-on”—it is the core of our process. Our clients rely on us because we spot problems before they cost you money or time.

Before any quote or production, we have senior engineers review your design for DFM, ensuring every detail fits the reality of CNC machining.

Our Four-Step DFM Optimization Workflow

- Material and Geometry Review: We check alloy choice, feature size, and geometry for machine compatibility.

- Tolerance and Finish Analysis: We identify critical tolerances and finishes, and flag non-essential specs for cost savings.

- Machining Simulation: Our engineers run toolpath simulations to uncover inefficiencies or risk areas.

- Client Feedback and Revision: We provide clear, actionable suggestions to improve manufacturability and reduce cost.

By collaborating early, we help you realize:

- Faster and more accurate quotations.

- Predictable production lead times.

- Higher first-pass yield with fewer reworks.

- Greater confidence in global shipments.

Table: Prime’s DFM Review Checklist

| Review Step | Typical Issues Found | Solutions Provided |

|---|---|---|

| CAD Model Check | Unmachinable features | Suggested geometry adjustments |

| Drawing Analysis | Overly tight tolerances | Recommendations for balanced specs |

| Simulation | Unreachable toolpaths | Tool or process modifications |

| Packaging Review | Poor protection for parts | Custom packaging solutions |

What Are the Most Costly DFM Mistakes for CNC Part Buyers?

Many buyers—even experienced ones—unintentionally design parts that drive up cost or lead to failure. I often help clients fix issues like these before they cause trouble:

1. Specifying undercuts that require expensive custom tooling.

2. Mixing metric and imperial units on the same drawing, leading to confusion.

3. Requesting surface finishes that add hours to machining time but serve no functional need.

4. Tolerances that far exceed application requirements, multiplying inspection costs.

5. Unclear or missing datum points, causing misalignment in multi-part assemblies.

How Prime Prevents Costly Errors

With every order, we:

- Audit the entire drawing and 3D file for manufacturability.

- Simulate real-world machining steps for each feature.

- Flag and correct risky or ambiguous details.

- Propose design alternatives that preserve function and boost production speed.

Table: DFM Errors and How Prime Fixes Them

| DFM Error Example | Resulting Problem | Prime’s Solution |

|---|---|---|

| Tiny corner radii | Tool breakage | Increased fillet size |

| Excessive tolerance callouts | Unneeded cost, inspection | Focused critical tolerances |

| Complex pocket depth | Tool deflection, scrap | Optimized geometry |

| Undefined surface finish | Inconsistent appearance | Standardized callouts |

How DFM Affects Lead Time, Cost, and Quality

Your bottom line depends on more than just price per part. DFM optimization unlocks:

- Faster response to RFQs.

- Reliable lead times and on-time deliveries.

- Lower rejection rates at both our factory and your site.

- Predictable, competitive costs even as volumes scale.

Buyers who embrace DFM consistently report smoother launches, better supplier relationships, and fewer production “fire drills.”

Case Study: DFM Optimization Saves Time and Money

A North American automation client sent us a project with complex steel brackets:

- Initial drawing had 12 different hole sizes, ±0.005mm tolerances on all faces, and deep, narrow slots.

- We suggested consolidating hole sizes, reducing tolerances to only critical faces, and revising slot depth for standard tool access.

Results:

- Production lead time cut from 26 days to 13 days.

- Rejection rate dropped from 7% to under 1%.

- Customer saved $8,700 on a 2,000-unit batch.

Table: CNC Project Metrics Before and After DFM

| Factor | Before DFM | After DFM |

|---|---|---|

| Lead time (days) | 26 | 13 |

| Cost per part (USD) | $15.60 | $10.25 |

| First-pass yield (%) | 92.5 | 99.1 |

| Quality rejections (#) | 150 | 18 |

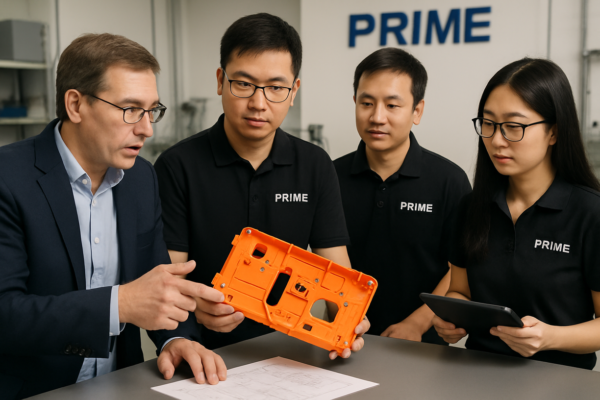

How Does Prime’s DFM Service Support Global B2B Buyers?

Our experience with North America, Europe, Middle East, and Australia means we understand the demands of global procurement.

Prime supports you with:

- Native English-speaking engineers and detailed communication.

- ISO 9001-certified processes and full traceability.

- Rapid design iterations and sample runs.

- Reliable packaging and logistics to prevent transit damage.

How Our Clients Benefit

- No more “lost in translation” moments—our bilingual team understands your needs.

- Proactive updates from prototyping to mass production.

- Flexible order volumes: prototypes, pilot runs, and mass orders all receive the same attention.

- Secure packaging designed for air, sea, or road freight.

- Full documentation (COC, material certificates, packing lists, inspection reports).

FAQs: DFM and CNC Machining for Metal Parts

1. What is DFM and why does it matter for CNC parts?

DFM means Design for Manufacturability. It ensures your part design fits real machining limits. For CNC, this means faster, more reliable production and better quality.

2. When should I involve DFM in my project?

You should ask for DFM input before finalizing your drawings. Early feedback from your supplier prevents mistakes and reduces revisions later.

3. Can Prime help revise my CAD files for manufacturability?

Yes, we provide free DFM review with each RFQ. Our engineers will highlight issues and propose solutions, improving your design before production.

4. What features most often cause CNC manufacturing problems?

Sharp internal corners, deep pockets, thin walls, over-tight tolerances, and poorly defined datums are common culprits. We check for all these on every order.

5. Does DFM only help with large-volume projects?

No, DFM benefits any project—prototypes, small batches, or mass production. Good DFM cuts time and cost at every stage.

6. What documents do I need for a DFM review?

We recommend sending:

- 3D CAD file (STEP, IGES, or SolidWorks)

- 2D technical drawing with tolerances

- Expected order quantity

- Description of end use and any special requirements

7. What certifications does Prime offer for CNC parts?

Our factory is ISO 9001 certified. We provide RoHS, REACH, and custom documentation on request.

8. How quickly can Prime deliver after DFM approval?

Standard CNC batches ship in 7–20 days after final drawings are signed off, depending on complexity.

9. Can DFM help me lower project costs?

Yes! Most customers save 10–40% after design changes from our DFM advice. We always optimize for both manufacturability and cost.

10. What if I need custom packaging for my CNC parts?

No problem. We design packaging for each project’s needs—foam, custom trays, vacuum sealing, and export crates to prevent transit damage.

Additional Real-World Examples and Visuals

Complex Housing Redesign Saves Money

A European automation customer needed aluminum housings with tight internal radii and deep slots. We added larger fillets, unified cavity sizes, and suggested thicker walls for rigidity.

Outcome:

- Part cost cut by 30%.

- No more tool breakage.

- 98% first-pass yield.

Custom Fastener Optimization

A US buyer ordered a run of fasteners with non-standard threads and extra-long shanks. We suggested using standard thread sizes and shortening the shank to fit existing tooling.

Outcome:

- Lead time cut by 10 days.

- $2,400 saved in tooling.

- 100% on-time delivery.

Why Choose Prime for DFM-Optimized CNC Manufacturing?

- Founded in 1993, over 20 years of industry experience

- Ten in-house production lines for flexible capacity

- ISO 9001-certified, global B2B partner

- Custom DFM review, clear communication, and fast lead times

- Stable, repeatable quality—no matter the order size

We are not just a supplier. We act as your technical partner from design to finished product. Our DFM-first mindset helps you unlock the full potential of CNC manufacturing.

Conclusion

DFM optimization ensures your CNC parts are made right—fast, cost-effectively, and reliably, from your first idea to global delivery.

Ready to take your CNC projects from design to flawless production?

Contact Prime. now for a free DFM review, expert consultation, and a tailored quote.

Experience fast lead times, ISO-certified quality, and true partnership—start by sending your inquiry on our website today.