Solution Of Precision Metal Welded Parts For Global Industry

Prime---Your Trusted Factory Since 1993

Common Products of Metal Welding Parts

Prime delivers precision-welded metal components tailored for structural, mechanical, and industrial applications across multiple industries.

Sheet Metal Welding Assemblies

Welded enclosures and brackets crafted from thin sheet metal with high precision. Widely used in electronics, cabinets, and control boxes.

Welded Structural Frames

Heavy-duty frames and base structures welded from tubes and beams for equipment, machines, and automation systems.

Robotic Welded Assemblies

Automated welding ensures consistency and strength for high-volume welded parts. Ideal for automotive and appliance industries.

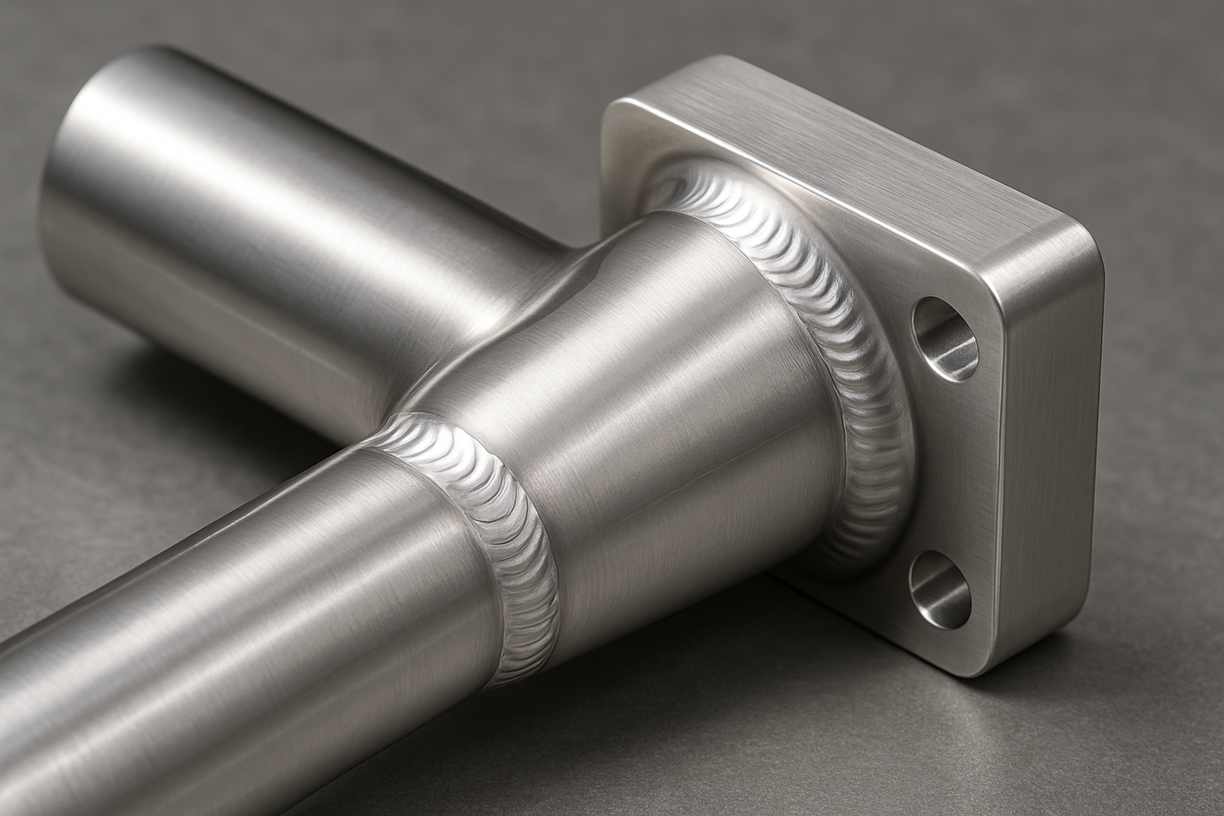

Stainless Steel Welded Parts

Corrosion-resistant weldments for food-grade, medical, or marine applications where hygiene and durability are critical.

Pipe Welding Assemblies

Custom welded piping structures for fluid transfer, HVAC, and mechanical systems, ensuring leak-proof and stable connections.

Welded Subassemblies

Integrated welded components designed to simplify final assembly and improve structural integrity in complex systems.

Why Prime: the strategic advantage of metal welding solutions

Choosing the right supplier for custom welded metal components is a strategic decision that impacts structural integrity, project timelines, and cost efficiency. With decades of fabrication expertise, advanced welding technology, strict ISO-certified quality systems, and a customer-first mindset, Prime has become the go-to partner across multiple industries. Our scalable production capacity, diverse welding capabilities, and global shipping support make us your ideal source for all custom metal welding needs.

- 30+ Years of Fabrication Expertise: Founded in 1993, Prime delivers proven performance in custom structural and precision welded parts across industrial applications.

- ISO 9001:2015 Certified Workflows: Our entire welding process—from raw material preparation to final inspection—complies with strict international quality standards.

- 10+ Dedicated Welding Lines: From MIG, TIG to robotic welding, we handle high-mix, high-volume demands with consistent quality and efficiency.

- Global Projects, Reliable Delivery: With customers across North America, Europe, the Middle East, and Australia, we offer efficient worldwide logistics and packaging solutions.

- Integrated Metal Fabrication: We combine welding with sheet metal forming, cutting, machining, and finishing—all under one roof to reduce lead times and communication gaps.

Ready to Build Stronger, Smarter Structures with PRIME?

Upload your drawings or technical specifications securely, and our welding engineers will conduct a feasibility review and provide a competitive quote within 24 hours.

Let’s bring your custom welded components to life—on time, on spec, and on budget.

Address Your Concerns: FAQ about Custom Metal Welding

To help our customers better understand our metal welding capabilities, we’ve compiled a list of frequently asked questions about custom welding services. These clear, practical answers are aimed at solving common concerns and guiding you to make informed decisions—avoiding delays, errors, and communication gaps in your projects.

What types of welding processes do you offer?

PRIME provides MIG, TIG, spot welding, robotic welding, and arc welding for different part sizes and material types. Each process is selected based on strength requirements, material thickness, and application environment to ensure the best balance of strength and appearance.

Can you fabricate large or structural welded assemblies?

Absolutely. PRIME specializes in both small precision brackets and large-scale welded frames. We support batch fabrication of base frames, machine housings, pipe supports and other heavy-duty structures, including lifting lugs and assembly-level tolerance control.

What materials can you weld, and is certification available?

We weld mild steel, stainless steel, aluminum, carbon steel, and structural alloys. All raw materials are traceable and can be provided with certifications such as EN10204 3.1, RoHS, REACH, or mill test reports upon request. Welders are certified per project need (AWS D1.1, ISO 9606-1).

Do you support welding design optimization or DFM suggestions?

Yes. Our engineers provide DFM (Design for Manufacturability) feedback to simplify weld joints, reduce deformation risk, and improve structural integrity. We review drawings and propose changes that maintain function while reducing labor time or welding distortion.

How do you ensure welding quality and dimensional accuracy?

We follow WPS/WPQ welding procedure standards and conduct full in-process and post-weld inspections. Our QC team uses CMMs, gauges, and visual inspection methods. Dimensional checks and weld reports are issued per batch to guarantee every weld meets tolerance and visual quality standards.

Do you export welded assemblies internationally?

Yes, we export globally with support for FOB, CIF, and DDP terms. All welded parts are packed with rust prevention oil, PE foam, moisture-proof layers, and wooden crates if required. We assist with customs documentation and compliance for seamless delivery to your destination.

Our Factory Insight

- Ⅰ: What is a Custom Metal Welded Part?

- Ⅱ: Reveal Custom Metal Welded Parts and Our Processes

- Ⅲ: Material Selection Guide for Custom Welded Metal Assemblies

- Ⅳ: Surface Finishing for Welded Metal Components

- Ⅴ: Joint Design & Fixturing: Precision from the Ground Up

- Ⅵ: Quality Assurance from Weld to Inspection

- Ⅶ: Common Welding Defects & PRIME’s Prevention Strategy

- Ⅷ:Versatile Applications: The Impact of PRIME Welded Metal Assemblies

- Ⅸ:How to Choose the Right Welded Parts Supplier

- Ⅹ:Design for Manufacturability (DFM) in Custom Welded Components

- Ⅺ:Explore Custom Metal Welded Parts – Strength Meets Precision

- Ⅻ:Global Logistics for Welded Metal Assemblies — Delivery You Can Rely On

- XIII: R&D and Innovation in Welded Assemblies – Building Smarter, Stronger Structures

- XIV: Value-Added Welding Services – From Fabrication to Final Assembly

- XV: More About Custom Welded Metal Parts

Ⅰ: What is a Custom Metal Welded Part?

Custom metal welded parts are fabricated by joining two or more metal pieces through high-heat fusion, forming a single strong and durable component. These parts are often tailored to meet specific load-bearing, structural, or assembly needs, making them indispensable in construction, machinery, and industrial systems.

Welding offers design flexibility, strength, and seamless joints that outperform traditional mechanical fastening in demanding environments. It accommodates various metals and allows for the assembly of complex structures that are lightweight yet highly durable.

Key Characteristics of Metal Welded Parts

• Strong Structural Integrity

Welding fuses metals at the molecular level, ensuring superior strength and reliability, even under high stress or vibration conditions — ideal for structural and load-bearing components.

• Material Versatility

Compatible with a wide range of metals such as carbon steel, stainless steel, aluminum, and special alloys — selected based on strength, corrosion resistance, and fabrication needs.

• Customized Geometries

Supports custom layouts, reinforcements, frames, and enclosures with complex geometries — tailored to your engineering drawings and functional specifications.

• Scalable Fabrication

Perfect for both prototypes and mass production, metal welded parts are efficiently fabricated with minimal tooling, short lead times, and high consistency.

Common Welding Techniques We Use

- MIG Welding (GMAW): Efficient and clean welding process suitable for medium to thick metals, offering strong and aesthetically clean joints.

- TIG Welding (GTAW): High-precision method used for thin materials and critical welds requiring exceptional appearance and low distortion.

- Arc Welding (SMAW): A versatile and robust method used in structural fabrication and heavy-duty parts with thick cross-sections.

- Spot Welding: Common in sheet metal assemblies, applying localized heat and pressure to create strong, discrete welds.

- Laser Welding: Delivers highly focused energy for micro-welding and minimal heat-affected zones in delicate or precision components.

- Robotic Welding: Ensures consistent weld quality and efficiency in large-scale or repetitive production runs.

Industries That Rely on Custom Welding

• Construction & Infrastructure

Welded beams, columns, braces, and heavy-duty supports for buildings, bridges, and infrastructure projects.

• Industrial Machinery

Frames, enclosures, robotic arms, and machine bases that require load handling, vibration resistance, and long service life.

• Agriculture & Equipment

Customized welded parts for tractors, plows, tillers, and harvesting systems operating under rough conditions.

• Transportation

Welded components in trailers, railcars, and transport machinery requiring fatigue resistance and high strength-to-weight ratios.

• Energy & Power

Welded pipe spools, pressure vessels, and supports used in oil & gas, wind, solar, and power generation sectors.

Ⅱ: Reveal Custom Metal Welded Parts and Our Processes

Whether you're new to custom welded components or seeking better fabrication solutions, this section provides a clear overview of how industrial welding works and how PRIME delivers robust and precise metal assemblies. We outline fundamental techniques, explain our capabilities, and show how we solve common pain points like strength, alignment, and scalability. Our goal is to help you make smart sourcing decisions backed by expert insight.

What is metal welding? A practical introduction

Welding is a manufacturing process that fuses metal parts together using high heat, pressure, or both to create a strong, permanent bond. It is essential for structural assemblies, brackets, enclosures, and frames across industries like construction, heavy machinery, and energy. Our factory leverages both manual and robotic welding to deliver custom solutions with outstanding strength, dimensional accuracy, and repeatability.

Choosing the right welding technique: tailored strength for your application

Selecting the optimal welding method ensures structural integrity, cost-efficiency, and functional performance. At PRIME, we tailor every weld job to your material type, joint configuration, and load conditions. Our engineers review your part drawings and application context to recommend the most effective approach. Below are our core welding capabilities:

1. MIG Welding: fast and reliable

MIG (Metal Inert Gas) welding is highly efficient and ideal for medium to thick parts that require strong, clean welds. PRIME uses semi-automatic and robotic MIG systems for large production runs, ensuring minimal distortion and strong fusion. This process is well-suited for carbon steel and stainless steel assemblies like frames, brackets, and supports.

2. TIG Welding: high precision and clean finish

TIG (Tungsten Inert Gas) welding is used for thin or delicate parts requiring fine detail and cosmetic quality. Our TIG specialists achieve low heat input and clean beads on stainless steel, aluminum, and titanium parts. It's ideal for food-grade containers, medical equipment frames, and intricate enclosures with tight tolerances.

3. Robotic Welding: speed meets consistency

Robotic welding enables consistent, high-speed welding for repetitive parts and high volumes, ensuring zero human deviation. We deploy multi-axis welding robots for automotive, agricultural, and structural assemblies requiring repeatability and cycle efficiency. This method minimizes rework and ensures scalable quality at lower cost per part.

4. Post-Weld Finishing: clean, inspect, and protect

After welding, we perform finishing processes such as grinding, polishing, sandblasting, and NDT inspection to ensure quality and aesthetics. Each part is evaluated for alignment, weld penetration, and surface appearance before painting or coating. PRIME maintains strict QA standards to ensure all parts meet your application’s structural and visual requirements.

Expert advice for custom welded assemblies

To help us deliver optimal results, please share part drawings, weld symbols, material specs, and expected loads early in the RFQ process. This allows our engineering team to recommend the best welding method and quality plan tailored to your needs.

Ⅲ: Material Selection Guide for Custom Welded Metal Assemblies

Material selection is the foundation of strong, reliable welded structures. At PRIME, we guide our clients in selecting the optimal metals for structural integrity, weldability, and end-use performance. Whether you're fabricating frames, enclosures, brackets, or high-stress parts — our experts help you balance strength, cost, corrosion resistance, and welding compatibility.

Common Welding Materials and Their Performance

| Material | Weldability | Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Carbon Steel (A36) | Excellent | 400–550 | Low | Frames, brackets, structural supports |

| Stainless Steel 304 | Good | 520–750 | High | Food equipment, enclosures, pipes |

| Aluminum 5052 | Moderate | 210–260 | Very High | Marine, transportation, decorative panels |

| Mild Steel (Q235) | Very High | 375–460 | Moderate | General fabrication, machine bases |

| Galvanized Steel | Low (requires prep) | 400–500 | Excellent (zinc coating) | Outdoor enclosures, ducts, cabinets |

PRIME's Engineering Support for Welded Assemblies

At PRIME, we go beyond welding — our team ensures that the chosen materials meet your design intent, strength targets, and environmental requirements.

Material Certification & Welding Suitability

We provide full traceability for all raw materials — including mill test reports (MTRs) and weldability assessments — ensuring the chosen material meets strength, compliance, and process needs.

DFM Review for Welded Structures

We evaluate every design for manufacturability — recommending joint types, material thickness, edge prep, and gap tolerances — to ensure strong welds and easy fabrication.

Total Cost & Weld Feasibility Evaluation

We help you balance performance and budget — evaluating not just material price, but weld time, filler usage, distortion risk, and surface finishing costs.

Ⅳ: Surface Finishing for Welded Metal Components

Surface treatments enhance the performance, appearance, and corrosion resistance of custom welded parts. PRIME offers a wide range of industrial-grade finishing options to ensure long-term reliability and aesthetics in demanding environments.

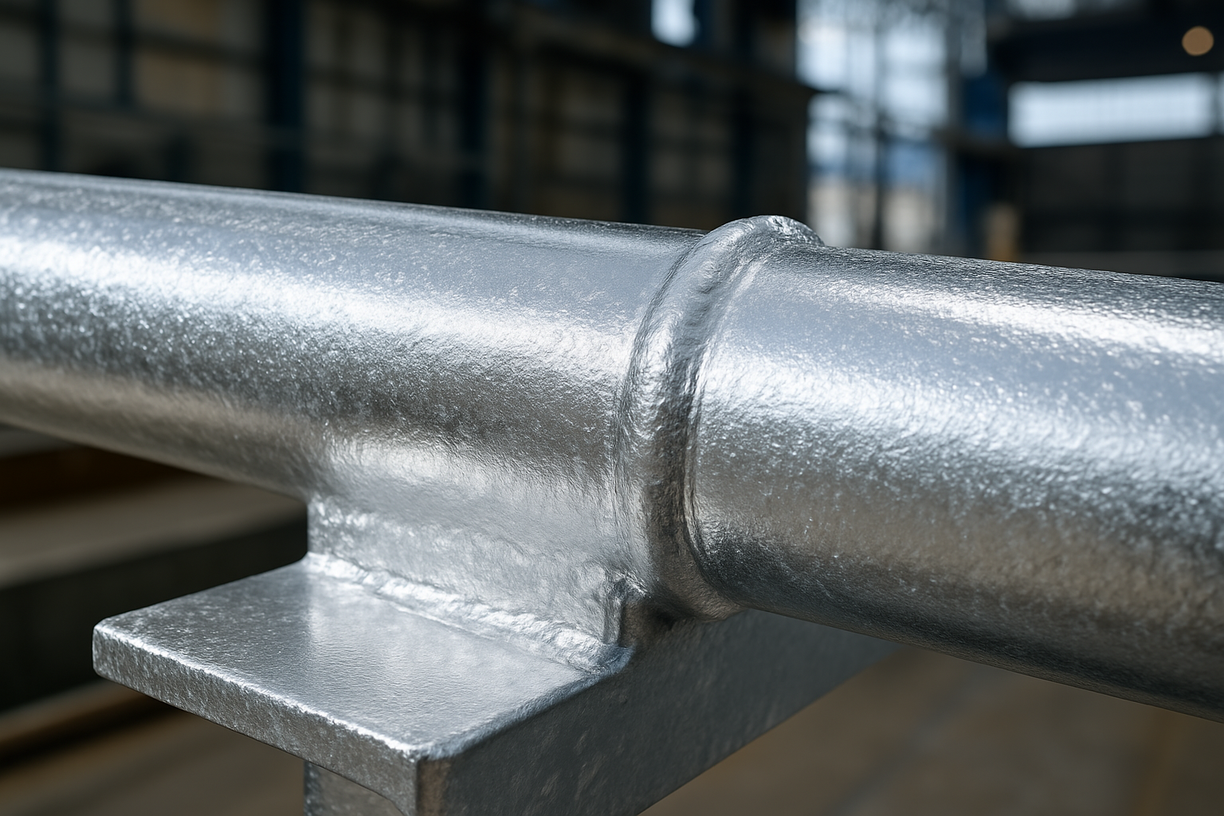

- Hot-Dip Galvanizing: Adds a protective zinc coating to steel components, providing exceptional corrosion resistance for outdoor or marine use.

- Powder Coating: Durable and uniform finish in customizable colors, excellent for visual appeal and impact resistance.

- Shot Blasting & Sandblasting: Removes scale and impurities, creating a clean surface for paint, powder coat, or further machining.

- Passivation (Stainless Steel): Chemically removes free iron and enhances corrosion resistance without affecting weld zones.

- Grinding & Polishing: Smooths weld seams and sharp edges, improving part safety and assembly accuracy.

- Custom Marking & Coating: We support engraved logos, serial numbers, and specialized coatings upon request.

Ⅴ: Joint Design & Fixturing: Precision from the Ground Up

Consistent and strong welds begin with smart design and robust fixturing. At PRIME, we create tailor-made welding jigs and validate every joint for ease of welding, strength, and distortion control.

- Weld-Oriented DFM: We assess corner joints, edge gaps, bevels, and welding angles for maximum accessibility and structural integrity.

- Custom Fixtures: CNC-machined fixtures ensure repeatability and tight tolerances across complex welded assemblies.

- Distortion Prevention: Strategic clamping and heat control minimize deformation, especially in thin-walled or multi-pass welds.

- Simulation & Testing: We digitally simulate thermal behavior and weld paths before production to prevent issues on the floor.

Ⅵ: Quality Assurance from Weld to Inspection

Our commitment to quality starts with raw materials and extends through welding, finishing, and inspection. PRIME applies industry best practices and international standards to ensure every welded part is compliant and reliable.

- Incoming Material Check: Spectral and mechanical tests confirm composition before welding begins.

- Welding Process Monitoring: Our certified welders follow WPS/PQR protocols and record key parameters for traceability.

- Non-Destructive Testing (NDT): Options include dye penetrant, ultrasonic, and X-ray inspections for critical welds.

- Dimensional Control: Final parts undergo visual, CMM, and gauge-based inspections to confirm tolerances.

- Documentation & Compliance: We provide COC, welding maps, and full batch traceability upon request.

Ⅶ: Common Welding Defects & PRIME’s Prevention Strategy

Welding is a critical fabrication process where even small imperfections can compromise strength, alignment, or corrosion resistance. At PRIME, we implement certified procedures, skilled welders, and post-weld quality control to eliminate common issues and ensure structural integrity in every part.

1. Porosity

Description: Tiny gas pockets or voids inside the weld, weakening structural strength and sealing ability.

PRIME Solution: Use of clean, dry base material, correct shielding gas flow, and preheat techniques to prevent trapped gas.

2. Undercut

Description: Groove formed at the weld toe, reducing the cross-sectional area and stress capacity.

PRIME Solution: Optimized welding parameters and multi-pass techniques ensure even weld distribution with no edge erosion.

3. Incomplete Fusion

Description: Lack of proper bonding between weld metal and base metal, often caused by low heat input or poor technique.

PRIME Solution: Use of calibrated machines, consistent torch angles, and skilled welders trained to AWS standards.

4. Cracks (Hot or Cold)

Description: Fractures within the weld or heat-affected zone caused by excessive stress, poor design, or improper cooling.

PRIME Solution: Proper joint design, preheat and post-weld heat treatment (PWHT), and controlled cooling rates.

5. Weld Spatter

Description: Small metal particles that stick to the surrounding surface during welding, affecting aesthetics and assembly.

PRIME Solution: Anti-spatter sprays, tuned current settings, and post-process cleanup ensure smooth, clean surfaces.

Ⅷ:Versatile Applications: The Impact of PRIME Welded Metal Assemblies

Custom welded metal parts are foundational to countless industries requiring strength, stability, and engineered performance. From structural frames to pressure-bearing components, PRIME's welding capabilities adapt to varied specifications, ensuring precision joints and long-lasting durability.

1. Construction & Infrastructure

Impact: Requires heavy-duty welded parts capable of bearing dynamic and static loads.

PRIME’s Role: Fabricates structural steel supports, base plates, and connection joints with AWS D1.1 certified welding and hot-dip galvanized options.

2. Transportation & Heavy Vehicles

Impact: Exposed to vibration, dynamic stress, and impact over time.

PRIME’s Role: Provides custom frames, engine mounts, and brackets with full weld penetration and dimensional precision for trucks, trailers, and rail systems.

3. Agriculture & Mining Equipment

Impact: Must withstand abrasive materials, shocks, and outdoor exposure.

PRIME’s Role: Produces wear-resistant welded parts such as frames, scraper blades, and loader arms using Q345, HARDOX, and manganese steel.

4. Marine & Offshore Systems

Impact: Demands corrosion-resistant joints and long-term water-tight durability.

PRIME’s Role: Supplies stainless steel and galvanized structures for ship decks, docks, and underwater frames with TIG/MIG process integrity.

5. Industrial Automation & Robotics

Impact: Requires vibration-stable and geometrically consistent welded structures.

PRIME’s Role: Delivers machined weldments and sensor-mounted bases with low-deflection tolerances and laser-verified flatness.

From load-bearing baseplates to marine-grade structures — PRIME's welded metal assemblies meet the unique needs of each industry.

Share your technical drawings or functional requirements with us — our welding experts will recommend the optimal material, joint type, and finishing process.

Request a Welding ConsultationⅨ:How to Choose the Right Welded Parts Supplier

Selecting a reliable supplier for custom welded metal components is critical for project safety, functionality, and cost-efficiency. Beyond pricing, consider their welding certifications, inspection capabilities, and ability to meet your technical and timeline needs. Here's what to evaluate before choosing a long-term welding partner.

1. Welding Certifications & Standards

- Is the supplier qualified under AWS D1.1, ISO 3834, or EN 1090 standards?

- Do their welders hold WQT/WPS/PQR documentation?

- Can they meet industry-specific standards (e.g., offshore, pressure vessels, medical)?

🧪 Tip: Ask to review past welding procedure specs and welder qualification records.

2. Material Handling & Welding Capability

- Do they specialize in mild steel, stainless, aluminum, or alloy steels?

- Can they perform MIG, TIG, and robotic welding based on your part geometry?

- What is the thickness range they can handle?

⚙️ Tip: Request sample weld beads and joint strength test results.

3. Inspection & Testing Protocols

- Do they perform visual, ultrasonic (UT), dye penetrant (PT), or X-ray testing?

- Are their inspectors certified under ASNT, ISO 9712, or equivalent?

- Can they deliver weld maps, NDT reports, and COC documents?

🔍 Tip: Review sample inspection logs and heat treatment reports.

4. Production Scale & Project Flexibility

- Can they manage both low-volume prototypes and large-batch production?

- Do they offer modular assembly, welding jigs, and multi-station setups?

- How fast can they scale production and handle urgent requests?

📈 Tip: Ask about their lead time guarantees and overtime shift options.

5. Engineering Support & CAD Collaboration

- Do they review and adjust your weld drawings and GD&T details?

- Can they offer design for welding (DFW) improvements?

- Do they simulate stress, warping, or cooling distortion?

🖥️ Tip: Look for suppliers who use SolidWorks, AutoCAD, or ANSYS simulation tools.

6. Delivery, Export & Service Location

- Are they familiar with export packaging, sea freight, and labeling?

- Do they offer shockproof pallets, rust prevention, and export documentation?

- Where are they located and how do they handle international logistics?

🚢 Tip: Choose a partner with proven international shipping experience and customs compliance.

At PRIME, we meet global welding standards, deliver full documentation, and support every stage from design consultation to shipment. With 10 welding lines and 30+ years of experience, we serve industries that demand excellence.

Ⅹ:Design for Manufacturability (DFM) in Custom Welded Components

Optimize structural integrity, simplify fabrication, and minimize rework with our expert welding-oriented DFM strategies.

What is DFM for Welding? In metal fabrication, Design for Manufacturability means shaping your component designs in ways that support efficient, reliable, and cost-effective welding. It involves thinking about joint types, weld access, distortion control, and inspection readiness before the torch is lit.

At PRIME, our DFM support for custom welded parts ensures your drawings are not only structurally sound but also practical for real-world welding — improving outcomes while cutting costs and delays.

Buyer’s concern: “My design includes thick-to-thin transitions, tight corners, and multiple welded joints. I'm worried about distortion, failed welds, and inspection challenges. How can I optimize the design before production?”

1. Joint Design & Welding Feasibility

- Access Optimization: Ensure welds are accessible for both manual and robotic welding tools.

- Minimized Weld Volume: Reduce bead size without sacrificing strength through optimal joint geometry.

- Weld Symbol Clarity: We help ensure your 2D drawings clearly communicate weld types, sizes, and finishing expectations.

2. Material Pairing & Weldability

- Compatible Metals: Avoid material combinations prone to cracking, warping, or corrosion after welding.

- Preheat & Postheat Requirements: We assess metallurgy to reduce unnecessary steps and reduce energy use.

- Weld Process Matching: Select MIG, TIG, or Spot Welding based on material thickness and strength goals.

3. Distortion Prevention & Fixture Planning

- Sequence Planning: Recommend weld orders that reduce heat buildup and part movement.

- Fixture Integration: Design components to simplify clamping or allow fixture-free alignment.

- Balanced Welding: Distribute welds symmetrically to mitigate stress concentration.

4. Inspection Readiness & Standards Alignment

- NDT Accessibility: Design for easy ultrasonic, X-ray, or visual inspection of weld zones.

- ISO/ASME Standards: Ensure drawings align with ISO 5817, AWS D1.1 or customer-specific specs.

- Traceability Planning: Enable batch control and part traceability for critical welds.

Our DFM support isn't just about welding better — it's about welding smarter. We work directly with your design team to validate manufacturability before cutting metal, ensuring stability, compliance, and cost control from day one.

Partner with PRIME to make every weld stronger, faster, and more economical — without sacrificing quality.

Ⅺ:Explore Custom Metal Welded Parts – Strength Meets Precision

Custom welded metal assemblies are the backbone of structural stability and design flexibility across industries like construction, automotive, energy, and machinery. At PRIME, we specialize in delivering fully customized, high-strength welded components that meet international standards and your unique design specs — whether you're building for durability, precision, or performance.

Why Choose PRIME Welded Assemblies?

- End-to-End Customization: From design review to welding method selection (MIG, TIG, Spot), tailored for your part’s function.

- Strong, Durable Joints: Engineered to withstand mechanical stress, vibration, and harsh environments.

- Certified Welders & Processes: All production follows ISO, AWS, and customer-specific welding codes.

- Weld Quality Assurance: NDT, visual, ultrasonic, or X-ray inspection available for structural-critical parts.

- Integrated Fabrication: Welding combined with stamping, CNC, bending, and finishing in one seamless process.

Application Examples

- Structural frames and mounting brackets

- Battery enclosures and EV system supports

- Industrial machine housings and chassis

- Architectural steel components

- Railway undercarriage parts

- Oil & gas pipeline supports

- Medical equipment frameworks

- Heavy-duty welded subassemblies

Our Welding Workflow

- Technical drawing & weld analysis

- Material selection & cut preparation

- Fixture design for alignment

- Manual or robotic welding execution

- Post-weld stress relief or grinding

- Final inspection & documentation

Quality You Can Trust

Our welded parts go through strict quality gates — including dimensional inspection, weld penetration checks, and surface finish control. We comply with ISO 9001, AWS D1.1, and ASME Section IX standards, ensuring confidence in every load-bearing structure.

Ⅻ:Global Logistics for Welded Metal Assemblies — Delivery You Can Rely On

For custom welded parts, shipping isn't just about distance — it's about protection, timing, and traceability. At Prime, we combine precision welding with robust global logistics to ensure your fabricated components arrive on time, intact, and fully documented — no matter your location.

Buyer Concern

“Our welded frames are large, heavy, and critical to the assembly line. Can Prime guarantee secure international delivery without delays or damage?”

Prime's Welded Parts Shipping Solution

Whether you’re sourcing structural steel weldments or precision subframes, our logistics team ensures each order is handled with industrial-grade care — from crating to customs.

1. Freight Optimization for Bulky Weldments

- Wooden Crate Packaging: Custom pallets and skids for oversized welded frames.

- Multi-Point Reinforcement: Internal blocking and bracing for long-distance transit.

- Sea & Air Freight Expertise: We balance weight, volume, urgency, and cost.

2. Documentation & Compliance for Cross-Border Clarity

- Welding Certifications: EN/ISO/AWS documents included per request.

- HS Code Accuracy: Avoids costly border inspections and delays.

- Full Export Pack: Includes invoice, origin certificate, packing list, and inspection reports.

3. Damage-Resistant Packaging System

Welded parts are protected from corrosion, vibration, and impact:

- VCI film, foam lining, and edge protectors

- Heavy-duty straps and shrink wrap

- Seaworthy crating with treated wood

4. End-to-End Visibility & ETA Control

We offer real-time tracking and proactive alerts so you’re never in the dark:

- Tracking codes for all freight modes

- Notification on departure, customs release, and delivery

- Dedicated account manager communication

5. Global Inventory Programs

For OEM buyers and framework agreements, Prime offers regional warehousing, buffer stock, and JIT shipping to avoid bottlenecks and support just-in-sequence production globally.

Make Shipping the Easiest Part

Prime doesn’t just fabricate — we deliver. From heavy-duty frames to precision welded housings, trust us to handle the complexity of international logistics with industrial reliability.

XIII: R&D and Innovation in Welded Assemblies – Building Smarter, Stronger Structures

In today’s complex industrial landscape, metal welding is no longer just about joining parts — it’s about enabling high-performance structures that are lighter, stronger, and more cost-efficient. At PRIME, our welding-focused R&D efforts help clients push the limits of mechanical design, from lightweight frames to hybrid material assemblies.

Buyer Concern: Can my supplier keep up with structural requirements, evolving welding standards, and application-specific challenges like distortion, fatigue, or corrosion?

1. Advanced Weld Process Development

We tailor weld procedures (WPS/PQR) to specific project goals, exploring MIG, TIG, spot, and robotic welding for optimal results. R&D focuses on minimizing heat-affected zones, improving penetration control, and enhancing fatigue resistance in load-bearing structures.

2. Material Joining Innovation

- Dissimilar Metal Welding: Reliable joining of aluminum to steel or stainless to carbon using filler strategies.

- High-Strength Steel Programs: Developing best-practice sequences for ultra-high tensile materials like S700 or Hardox.

- Nonferrous Applications: Optimized welds for brass, copper alloys, and thermal-sensitive substrates.

3. Simulation & Digital Welding Validation

Using CAD-integrated simulation, we test fixture stress, warpage risks, and weld sequence strategies before fabrication even begins. We support clients with:

- Virtual welding paths and thermal simulation

- Clamping/fixturing design validation

- DFM + DFA optimization reports for weldability

4. Industry-Specific Customization

From EV battery racks to structural panels and medical housings, we build welded solutions tailored to your industry. Our engineers adapt joint design, weld length, distortion control, and surface prep for:

- Transportation & off-road machinery

- Medical devices and stainless assemblies

- Energy equipment, racks, and supports

Why PRIME for Welding Innovation?

PRIME’s welding R&D isn't just about joining metal — it's about pushing boundaries. Our team helps you reduce weld-related failure risks, shorten assembly cycles, and achieve compliance with demanding global standards. Whether you need certified prototypes or scalable production, we’re ready to weld what’s next.

Discuss Your Welded DesignXIV: Value-Added Welding Services – From Fabrication to Final Assembly

For buyers of custom welded parts, delivering a fully usable solution takes more than welding. PRIME provides a full range of post-weld processing, surface treatments, assembly, and packaging—so your structural components arrive exactly as needed, ready for integration or final use.

Buyer Concern

“After welding, I still need surface treatment, dimensional accuracy, labeling, and packaging. Can one supplier handle the entire chain with traceability and compliance?”

PRIME’s One-Stop Welding & Finishing System

From raw steel cutting to finished welded modules, PRIME offers full-process control and value-added steps. This reduces supplier handoffs, ensures repeatability, and helps you accelerate final product delivery.

1. Structural Welding & Joint Optimization

- MIG / TIG / Spot Welding: Adapted to geometry and load requirements.

- Multi-Material Jointing: Steel, stainless, aluminum, and brass integration.

- Full Weld Traceability: Certified operators and weld map documentation.

2. Surface Treatment & Appearance Control

- Sandblasting & Grinding: Cleaned, leveled, and burr-free surfaces.

- Powder Coating / Painting: Durable, aesthetic protection per RAL/Pantone.

- Galvanizing & Passivation: Long-term corrosion resistance for outdoor or industrial use.

3. Final Inspection & Dimensional Verification

- Coordinate Measurement (CMM): Verifying key dimensions and alignment.

- Weld Seam Testing: Visual, UT, or dye-penetrant inspection.

- Material Certificate + Reports: Delivered with each order when required.

4. Subassembly & Module Integration

- Threaded Inserts & Bushings: Installed post-weld.

- Machined Interface Plates: Added for hybrid assemblies.

- Fixture-Based Assembly: Accuracy maintained with calibrated jigs.

5. Cleaning, Deburring & Anti-Corrosion Prep

- Degreasing & Ultrasonic Wash: Removal of oils, spatter, and weld byproducts.

- Edge Rounding & Deburring: Safer handling and improved coating adhesion.

- VCI Film & Foam Wraps: Corrosion and impact protection during shipment.

6. Export-Grade Palletizing & Labeling

- Custom Pallet Frames: Designed for bulky welded items.

- QR Code & Batch Labels: Improve inbound traceability and tracking.

- ISPM 15 Certified Packaging: For global wood crate compliance.

Your One-Stop Welding Solution Provider

Whether you need ready-to-assemble racks, painted frames, or palletized welded kits—PRIME handles it all. We go beyond fabrication to ensure your project is delivered ready, reliable, and refined.

Simplify your sourcing, reduce risk, and deliver value at every stage of production.

Commonly Welded Materials

| Mild Steel (Q235, S235) | Carbon Steel (Q345, S355) |

| Stainless Steel (304, 316L) | Aluminum (5052, 6061) |

| Galvanized Steel | High-Strength Steel (S700, HARDOX) |

| Brass / Copper Alloys | Bimetallic Weld Joints |

Surface Finishing Options

| Powder Coating | Hot-Dip Galvanizing |

| Bead/Sand Blasting | Brushing / Polishing |

| Passivation (Stainless) | Electroplating (Zinc, Nickel) |

| Anti-Corrosion Primer | Custom Paint (RAL / Pantone) |

XV: More About Custom Welded Metal Parts

Discover our advanced welding capabilities, integrated assembly support, and full-process control that delivers structurally sound, inspection-ready, and application-optimized welded components.

Welding Process Capabilities

- MIG Welding (Manual & Robotic)

- TIG Welding for Stainless & Aluminum

- Spot & Projection Welding

- Structural Welding with AWS Standards

- Multi-Station Jig Welding

- Prototype to Mass Production

In Summary

Selecting the right welded component supplier isn’t just about cost—it’s about strength, precision, and dependability. This guide has explored PRIME’s end-to-end welding capabilities, from material selection and joint design to finishing and logistics. A reliable partner ensures not just compliance, but competitive advantage across every welded structure you deliver.

Key Insights for Welded Parts Buyers

- Structural Integrity First: The weld must hold under stress—choose a supplier skilled in distortion control, joint prep, and inspection.

- Finish & Functionality: Coatings, galvanizing, and polishing ensure both corrosion resistance and aesthetic value.

- Traceable Workmanship: Certified welders, WPS documentation, and third-party inspections matter—especially for safety-critical parts.

- Flexible Production: From small-batch prototypes to full-frame assemblies, agile capacity is essential.

- Packaging & Compliance: Export-ready packing, ISPM 15 crates, and proper labeling protect your investment during transit.

Why PRIME is Your Welding Partner

With over 30 years of fabrication expertise, PRIME delivers structural and cosmetic welds that meet global quality standards. From MIG to TIG and robotic lines, our engineers adapt processes for optimal strength, speed, and cost-efficiency.

We don’t just fabricate welded parts—we co-engineer your solutions, validate manufacturability, and ensure reliable delivery from blueprint to bulk shipment.

Global Fabrication, Local Precision

PRIME supports industrial clients worldwide—from construction and energy to medical and transport—with weldments that meet EN, AWS, and ISO standards. Our export-ready workflows include full customs documentation, batch traceability, and moisture-resistant packaging.

Wherever your project goes, PRIME ensures your welded structures arrive compliant, protected, and production-ready.

Let’s Build Better Welded Solutions

Whether you need precision-welded frames, protective housings, or full assemblies—PRIME delivers ready-to-install components backed by quality, speed, and experience. Share your project and get a weldability review and quote within 24 hours.

See why B2B buyers across industries trust PRIME for scalable welded solutions.

Get a Welding QuoteJust a Few of the Partners Who Trust Our Quality

*Logos are property of their respective owners.

What Our Customers Say

Real feedback from global buyers who trust us to deliver high-quality, customized industrial components.

Harry M., New York

Purchasing Manager – Metal Components

We’ve sourced CNC machined parts from Prime for over two years. The precision is consistently excellent, tolerances are spot on, and their team is responsive and professional. Fast lead times and secure packaging make them a reliable long-term partner.

Robert J., California

Strategic Sourcing Specialist – Industrial Hardware

The forged components we received from Prime were top quality — strong material integrity, accurate dimensions, and zero defects. Their team understood our specs clearly and delivered right on schedule. Great supplier for high-stress applications.

Emily T., Texas

Supply Chain Buyer – Custom Metal Parts

We ordered a batch of custom metal welded assemblies from Prime, and the quality was outstanding. The welds were clean, uniform, and met all our strength requirements. Communication was smooth, and delivery was faster than expected.

Hannah K., Ontario

Senior Buyer – Automotive

Prime supplies us with custom metal casting parts that meet strict automotive standards. Their ISO-certified quality, fast prototyping, and on-time delivery make them a trusted partner in our supply chain.

Luis R., Barcelona

Procurement Lead – Electronics

Prime has been a reliable partner for our custom plastic parts in consumer electronics. The injection-molded components are precise, durable, and always delivered on time, helping us stay competitive in the market.

Nadia P., Dubai

Category Manager – Industrial Projects

Prime delivers high-quality custom metal forgings for our industrial machinery. The parts are strong, reliable, and meet our exact specifications. With consistent quality and on-time delivery, Prime has become a trusted partner in our long-term projects.

Jon S., Munich

Operations Buyer – Machinery

Prime’s custom metal fasteners have proven to be durable and precise, perfectly fitting our heavy-duty machinery. Their consistent quality and reliable delivery help us maintain smooth production with fewer interruptions. Prime is a supplier we can count on for critical components.

Aisha M., Sydney

Sourcing Manager – Energy

From quoting to final inspection, Prime stayed on schedule with transparent updates. Their QC reports, salt spray results, and traceability made onboarding very smooth.

Get Your Custom Solution & Quote

REPLY WITHIN 24 HOURS

Start a Conversation with Our Experts

When you contact us, you get more than just a price. You get a dedicated partner.

- ✔ 30+ Years of Manufacturing Excellence, Direct from Our Factory

- ✔ Custom-Engineered Solutions for Your Needs

- ✔ Global Shipping & Logistics Support

- ✔ A Transparent, No-Obligation Quote

- ✔ 100% Confidentiality Guaranteed

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!