Solution Of Precision CNC Parts For Global Industry

Prime---Your Trusted Factory Since 1993

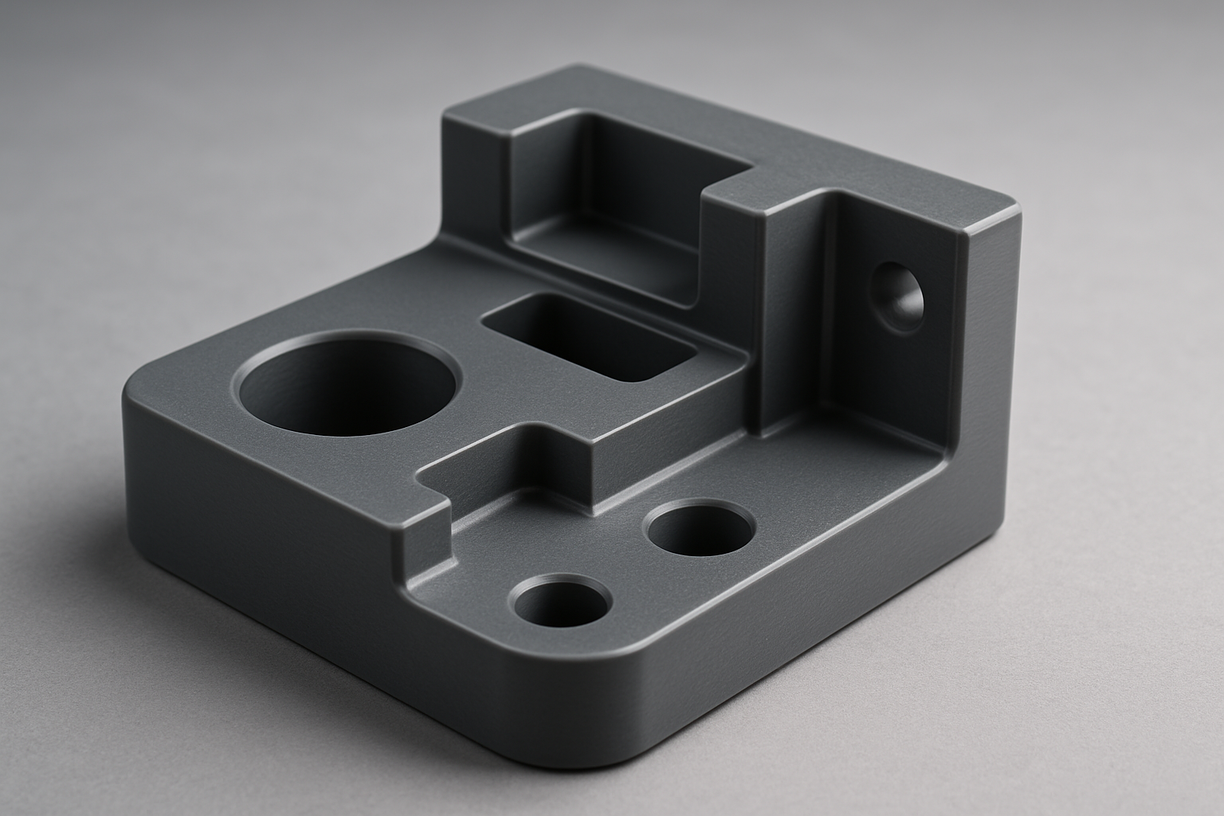

Common products of CNC parts

Prime offers a full range of high quality metal parts for a wide range of industrial, mechanical and manufacturing scenarios.

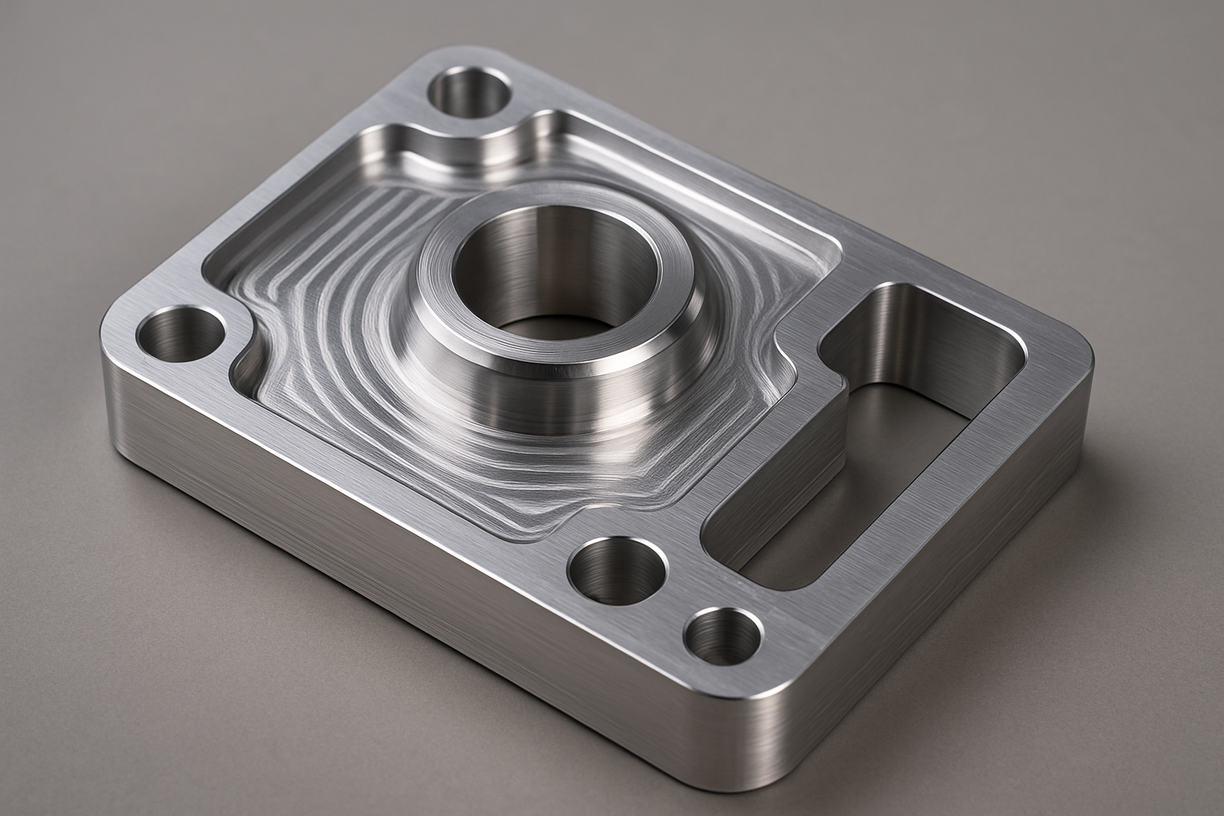

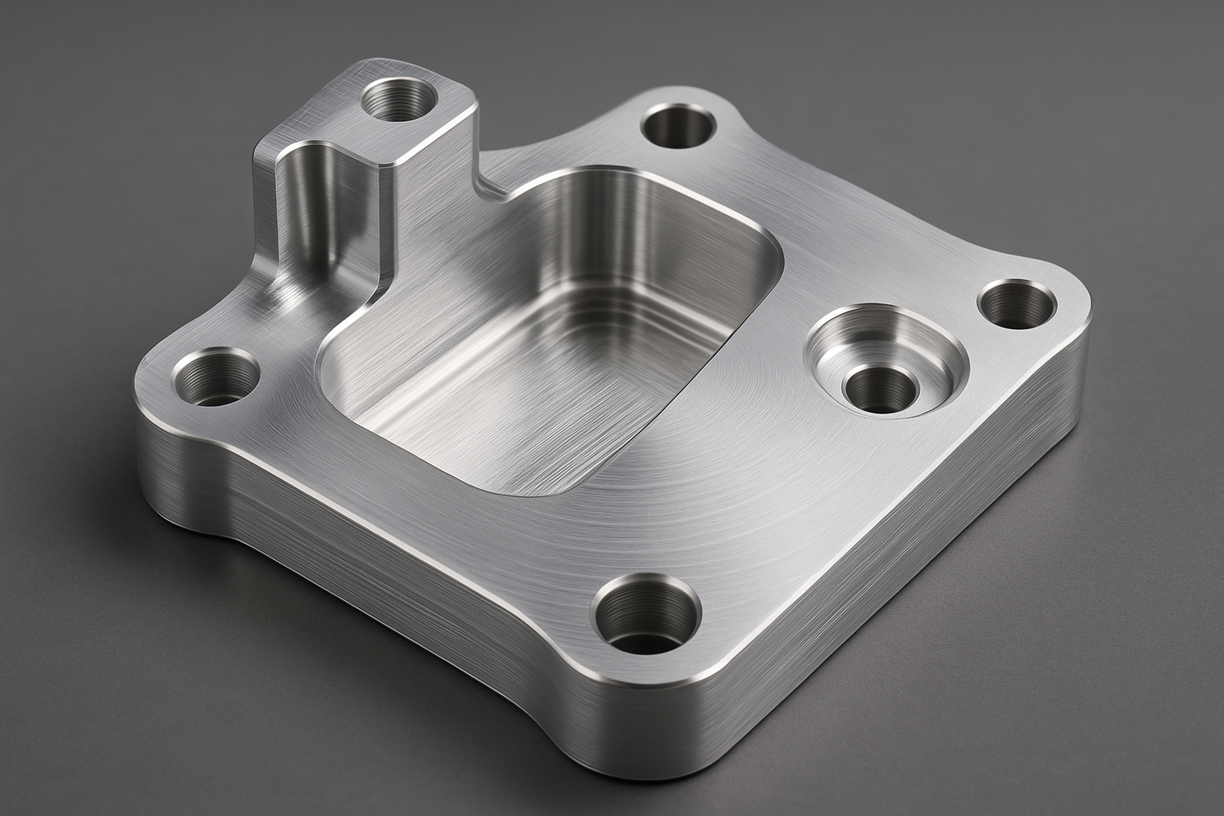

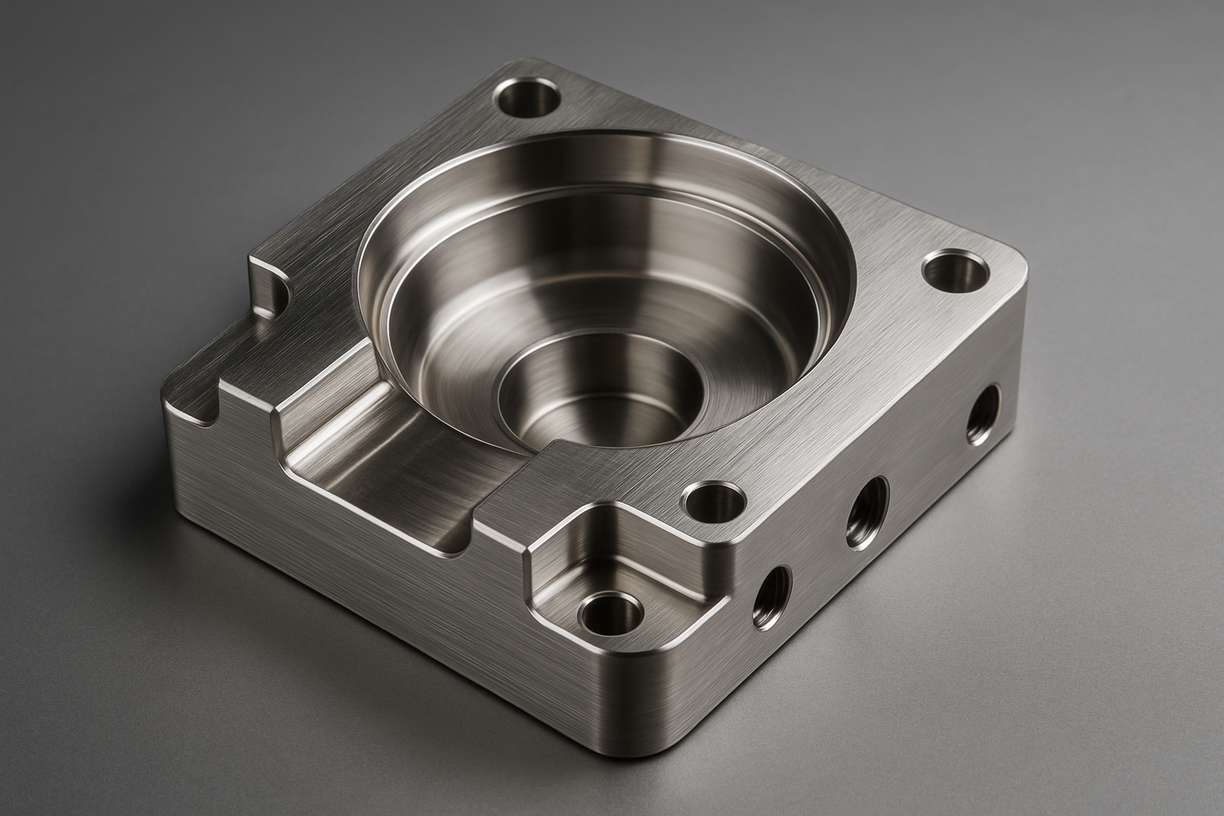

CNC Milled Parts

Flat or complex shapes are precisely machined by rotating cutting tools. Ideal for brackets, housings, and custom mechanical components.

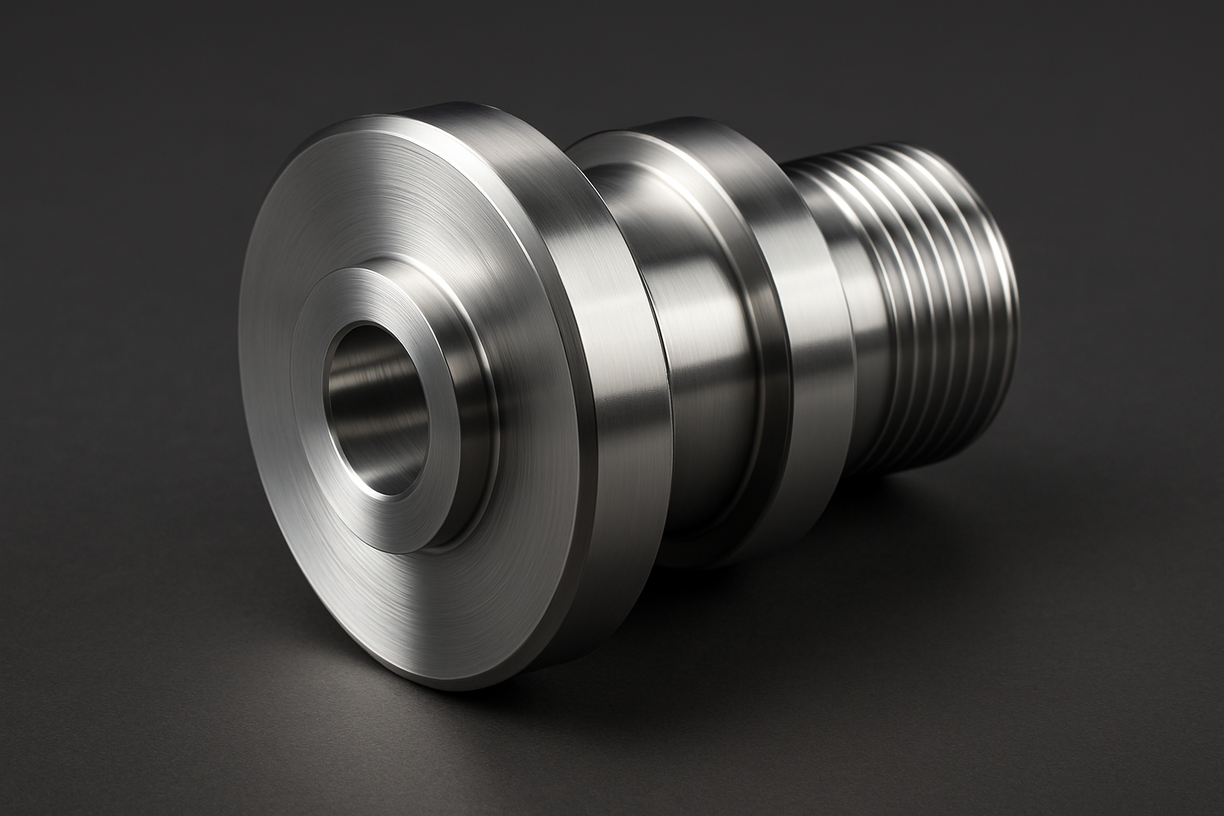

CNC Turned Parts

Cylindrical parts are produced on a lathe with excellent concentricity. Commonly used for shafts, pins, bushings, and threaded connectors.

CNC Aluminum Parts

Lightweight and corrosion-resistant, aluminum CNC parts offer good thermal conductivity and strength, widely used in aerospace and electronics.

CNC Stainless Steel Parts

Known for strength and corrosion resistance, these parts are essential in food processing, medical devices, and marine applications.

CNC Brass Parts

Brass provides high machinability and conductivity, making it ideal for fittings, valves, and electrical terminals.

CNC Plastic Parts

Precision-machined engineering plastics such as POM and Nylon offer insulation and wear resistance for non-metallic applications.

Why Prime: the strategic advantage of CNC parts supply

It is a strategic decision to choose a suitable supplier for CNC machining parts, which is directly related to product accuracy, project cycle and supply chain stability. Prime with decades of processing experience, advanced CNC equipment, strict quality control system and customer-centric service concept, the industry has become a trusted partner. We have efficient and flexible production capacity, precision processing technology and global coverage of logistics services, PRIME is to meet all kinds of CNC processing needs of your ideal choice.

- 30+ Years of Proven Expertise: Established in 1993, our deep industry knowledge empowers us to tackle complex challenges and deliver consistent excellence.

- ISO 9001:2015 Certified Quality: Our entire process—from material sourcing to final inspection—follows rigorous international standards to ensure reliable output.

- 15 Advanced Production Lines: Our high-speed infrastructure handles large orders with agility and scale, keeping your production timeline intact.

- Global Reach, Local Support: With exports to North America, Europe, the Middle East, and Australia, we ensure seamless international delivery and customs expertise.

- One-Stop Capabilities: Our comprehensive offering includes CNC parts, welded assemblies, castings, and fasteners—streamlining your supply chain with integrated solutions.

Ready to Experience the PRIME Difference?

Upload your drawings and specifications via our secure portal, and our engineering team will provide a full feasibility review and competitive quote within 24 hours.

Let’s build something extraordinary together.

Address Your Concerns: FAQ about CNC parts

To further assist our customers and provide comprehensive information, we have compiled a list of frequently asked questions about CNC parts and our services. Our goal is to solve common problems and provide clear, concise answers that will give you knowledge and confidence in your purchasing decisions, directly addressing the pain points of poor communication and lack of clarity.

How high can the machining accuracy be?

Prime's CNC machining supports precision up to ± 0.005 mm and is suitable for industrial parts where fit is highly desired. We are equipped with coordinate measuring machine (CMM) , altimeter, roughness tester and other advanced testing equipment, each batch of products are strictly according to the drawing inspection, and provide a complete size report and test records, to ensure that the customer assembly error-free, reliable operation.

Is it possible to customize complex CNC parts according to drawings?

Of course. We are good at customized according to customer drawings of various complex geometry or difficult structure parts, including special-shaped cavity, thin-walled components, curved surface fit, etc. . With a 5-axis machining center and a team of engineers with more than 10 years of experience, PRIME can assist in the whole process from design review, machining scheme to finished product delivery, and can provide DFM optimization suggestions, ensure that the design is both functional and easy to manufacture.

What are the common materials? Is proof of material provided?

We support CNC machining of a wide range of metals and engineering plastics, including aluminum (e. g. 6061,7075) , stainless steel (304,316) , carbon steel, copper, brass, and plastics such as POM and PTFE . All raw materials are sourced from traceable sources and can be certified on request, such as EN102043.1 certificates or RoHS, REACH and other environmental compliance documents to help customers ensure compliance and quality stability throughout the supply chain.

Can you assist with structural or process optimization recommendations?

Of course. Our engineering team has extensive experience in product Design for manufacturability (DFM) and is able to assist customers in the early stages of a project to evaluate the drawing structure and make recommendations that are more suitable for processing, reducing costs or improving performance. We support collaborative development to help customers optimize material selection, wall thickness, chamfering, processing path and other details without sacrificing functionality to achieve higher manufacturing efficiency and better use results.

How to ensure consistency and quality in mass production?

We have established a strict quality management system, has passed the ISO 9001 certification, and the implementation of the first confirmation, process inspection, final sampling and other multiple process control. Each process has a SOP and testing requirements, batch products before shipment unified testing and accompanied by size reports to ensure that the critical dimensions and tolerances are stable and consistent, to meet the quality requirements of long-term batch supply.

Does IT support international exports? How to arrange the packing and logistics?

Yes, PRIME has more than 20 years of export experience, customers in Europe and the United States, the Middle East, Australia and other places. We use multi-layer protective packing, including rust-proof oil, bubble wrap, moisture-proof bags, foam, cartons and wooden cases, etc. , to ensure that the products are moisture-proof, collision-proof and damage-free during long-distance transportation. At the same time support FOB, CIF, DDP and other international trade terms, and assist in the preparation of customs clearance documents to ensure that customers receive worry-free.

Our Factory Insight

- Ⅰ:What is a CNC Machined Part?

- Ⅱ:Reveal CNC Machined Parts and Our Processes

- Ⅲ: Material Selection Guide: The Key to CNC Machining Success

- Ⅳ:Surface Finishing for CNC Parts: Function Meets Form

- Ⅴ:Toolpath Planning & Fixture Design: The Foundation of Accuracy

- Ⅵ:Quality Assurance Across Every CNC Process

- Ⅶ:Common CNC Machining Defects & PRIME’s Prevention Strateg

- Ⅷ:Diverse Applications: The Impact of PRIME CNC Machined Parts

- Ⅸ:How to Choose the Right CNC Parts Supplier

- Ⅹ:Design for Manufacturability (DFM) in CNC Machining

- Ⅺ:Metal Stamping vs. CNC Machining: Choosing the Right Manufacturing Process

- Ⅻ:Global Supply Chain & Logistics: Seamless Worldwide Delivery

- XIII: PRIME CNC R&D & Innovation – Empowering Custom Precision

- XIV: Value-Added CNC Services – From Machining to Market

- XV: More About Custom CNC Machining

Ⅰ:What is a CNC Machined Part?

CNC machined parts are precision components produced by computer-controlled tools that remove material from a solid block (called a blank or workpiece) to create a desired shape. The CNC process uses pre-programmed software to automate milling, turning, drilling, and other machining operations with extreme accuracy and repeatability.

CNC machining is widely used to produce both simple and highly complex parts with tight tolerances. It supports a broad range of metals and plastics and is ideal for rapid prototyping, low-to-medium volume production, and functional end-use parts in industries requiring reliability and precision.

Key Characteristics of CNC Machined Parts

• Exceptional Precision

Modern CNC machines can achieve tolerances as tight as ±0.002mm (±0.00008 inches). Precision is maintained through high-rigidity setups, tool path optimization, and in-process measurement systems.

• Broad Material Compatibility

CNC machining supports materials like aluminum, stainless steel, brass, titanium, plastics (e.g., POM, PEEK), and exotic alloys. Each is selected based on mechanical, thermal, and cosmetic requirements.

• Complex Geometries

Multi-axis CNC machines enable production of intricate 3D shapes, undercuts, threads, curved features, and parts with mixed contours — all within tight tolerances and smooth surface finishes.

• Flexible Batch Sizes

Whether it’s a single prototype or full production run, CNC machining provides high-quality parts without the need for expensive molds or tooling, offering low lead times and agile manufacturing.

Common CNC Machining Processes

- Milling: Uses rotating cutters to remove material from flat and contoured surfaces in 3-, 4-, or 5-axis operations.

- Turning: Rotates the workpiece while a cutting tool shapes cylindrical or conical forms, often used for shafts and bushings.

- Drilling: Precisely creates holes and internal threads of varying depths and diameters.

- Tapping: Forms internal threads with high positional accuracy and consistency.

- Boring: Enlarges or finishes pre-existing holes to achieve high dimensional accuracy.

- Thread Milling: Produces precise and durable external or internal threads with superior chip evacuation.

Industries That Rely on CNC Machining

• Aerospace

Critical structural components, engine mounts, housings, and fittings with lightweight requirements and high reliability.

• Medical Devices

Machined surgical instruments, orthopedic implants, enclosures, and diagnostic parts requiring biocompatibility.

• Automotive

Precision engine parts, gearboxes, suspension components, and custom prototype parts for performance vehicles.

• Electronics

Housings, connectors, and heat sinks used in telecom, computing, and control system applications.

• Industrial Equipment

Customized shafts, bearings, brackets, and high-precision fixtures for automation, robotics, and manufacturing systems.

Ⅱ:Reveal CNC Machined Parts and Our Processes

Whether you're sourcing CNC machined parts for the first time or looking to refine your understanding, this section offers a clear overview of how CNC machining works and how PRIME delivers unmatched precision. We cover essential concepts, explain our capabilities, and demonstrate how our tailored solutions address typical challenges faced by industrial buyers. Our mission is to empower your decision-making with expert knowledge and proven strategies.

What is CNC machining? A practical introduction

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where computer-driven tools remove material from a solid workpiece to create precision parts. Using programmed tool paths and high-speed rotation, CNC can mill, turn, drill, and shape a wide range of metal and plastic materials. It’s highly effective for producing complex components in small to medium quantities with exceptional accuracy and consistency, serving industries like aerospace, automotive, and medical equipment.

Choosing the right machining method: tailored precision for your application

Selecting the most suitable CNC process ensures a perfect balance between quality, speed, and cost. At PRIME, we customize every job based on your specific material, tolerance, and design requirements. Our engineers will evaluate your part design and recommend the ideal machining method to optimize both functionality and price. Below are our core CNC processing techniques:

1. CNC Milling: complex geometry made simple

CNC milling is ideal for creating flat surfaces, slots, pockets, and intricate 3D contours, commonly used in structural components, housings, and mold bases. PRIME operates advanced 3-, 4-, and 5-axis mills to handle tight tolerance requirements and reduce the need for secondary setups. Our automated workholding systems and in-process measurements ensure micron-level accuracy and fast turnaround times.

2. CNC Turning: perfect for cylindrical parts

CNC turning is ideal for producing shafts, bushings, spacers, and threaded parts by rotating the workpiece against a cutting tool. Our high-speed CNC lathes with live tooling offer powerful multi-tasking, enabling turning, drilling, and threading in a single setup. PRIME ensures smooth surface finishes, high concentricity, and repeatable results across every lot.

3. 5-Axis Machining: unlock unlimited design freedom

5-axis machining allows simultaneous movement along five axes, enabling the production of intricate, multi-surface parts in one cycle. It’s ideal for aerospace, medical implants, and defense applications that demand high structural integrity and precision. At PRIME, our 5-axis equipment ensures tighter tolerances, reduced lead time, and fewer setups, all while maintaining consistent performance.

4. Drilling & Tapping: precision holes and threads

Drilling and tapping operations create precise holes and internal threads critical for assembly in electronics, automotive, and equipment parts. Our CNC centers use rigid tapping and peck drilling with real-time feedback to ensure optimal thread integrity and accuracy. We handle metric, imperial, and custom thread profiles, maintaining high consistency across batches.

Expert advice for informed CNC buyers

To help us recommend the most efficient and cost-effective machining method for your project, please share your target quantities, material specs, and critical tolerances early during the quoting phase. This allows us to fine-tune our setup and deliver exactly what your application demands.

Ⅲ: Material Selection Guide: The Key to CNC Machining Success

Choosing the right material is crucial in CNC machining — it influences the final part's durability, precision, and cost. At PRIME, we help clients navigate a wide range of metals and plastics, considering mechanical properties, surface finish, and machinability. With our experience, we ensure your material selection supports performance goals, compliance requirements, and cost-effectiveness.

Popular CNC Materials and Their Characteristics

| Material | Machinability | Strength (MPa) | Surface Finish | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061 | Excellent | 260–280 | Smooth, matte or polished | Enclosures, brackets, electronics housings |

| Stainless Steel 304 | Moderate | 480–510 | Bright, corrosion-resistant | Medical devices, fasteners, machinery parts |

| Brass C360 | Very High | 330–360 | Mirror-like, decorative | Valves, decorative hardware, sensor housings |

| Titanium Grade 5 | Low | 880–910 | Matte, biocompatible | Aerospace, implants, high-stress parts |

| POM (Delrin) | Excellent | 65–75 | Glossy, low friction | Gears, bushings, precision plastic components |

How PRIME Supports CNC Material Selection

We don’t just machine parts — we help you choose the most effective material for your project. PRIME provides full technical support and traceability to match your application’s functional, regulatory, and aesthetic requirements:

Material Certification & Testing

Each material batch is accompanied by chemical and mechanical certifications, confirming alloy composition, hardness, and tensile strength — ensuring compliance with international standards.

Machining-Oriented DFM Optimization

Our team assists in refining tolerances, wall thickness, and fillets according to material behavior — minimizing deformation, improving tool life, and reducing waste in CNC production.

Total Lifecycle Cost Evaluation

We consider not only the raw material price but also machining speed, tool wear, finishing requirements, and post-processing compatibility — helping you make informed choices with minimal long-term cost.

Ⅳ:Surface Finishing for CNC Parts: Function Meets Form

Surface finishing plays a crucial role in both the durability and precision of CNC-machined parts. At PRIME, we offer a variety of finishing options to meet different performance, cosmetic, and industry compliance needs, ensuring every part is ready for real-world application.

- Anodizing (for Aluminum): Improves wear and corrosion resistance, available in clear or colored finishes for aesthetic appeal and functional protection.

- Electroplating: Zinc, nickel, or chrome plating enhances surface hardness and corrosion resistance per ASTM B633 standards.

- Powder Coating: Ideal for components requiring a tough, UV-resistant finish, available in custom RAL/PANTONE colors.

- Bead Blasting: Achieves uniform matte textures that reduce glare and improve adhesion in later processes.

- Passivation: Enhances the corrosion resistance of stainless steel parts, ensuring biocompatibility in medical or food-grade use.

- Polishing and Deburring: Advanced manual and automated methods eliminate sharp edges and burrs for safety and precision assembly.

Ⅴ:Toolpath Planning & Fixture Design: The Foundation of Accuracy

Every precision CNC part starts with smart programming and secure fixturing. At PRIME, we combine CAD/CAM expertise with hands-on experience to ensure accurate machining and repeatable quality from prototype to mass production.

- DFM-Based Design Reviews: We optimize your designs for machinability, minimizing unnecessary complexity and cycle time.

- Toolpath Simulation: Advanced software detects collisions, undercuts, and feed-rate issues before the first cut.

- Custom Fixture Design: Dedicated jigs and fixtures for multi-face precision and reduced setup time.

- 5-Axis CNC Programming: Enables complex geometries with fewer setups, maintaining tight tolerances on all axes.

- Trial Runs & First Article Reports: We validate toolpaths under production conditions and provide full dimensional reports for approval.

Ⅵ:Quality Assurance Across Every CNC Process

From raw material inspection to final part verification, PRIME enforces strict quality control throughout the entire CNC production cycle. Our systems are designed to catch deviations early and maintain high-performance standards batch after batch.

- Raw Material Verification: MTC review and spectrometer checks ensure every bar or billet meets spec before cutting.

- In-Process Monitoring: Real-time measurements of key dimensions and tool wear using touch probes and automated inspection.

- Visual & Tactile Inspection: Each part is reviewed for surface defects, scratches, or tool marks before final approval.

- Final CMM Validation: Coordinate Measuring Machine (CMM) ensures all critical tolerances are met within ±0.005 mm accuracy.

- Compliance Documentation: Each batch includes a Certificate of Conformance (COC) with traceable data for full transparency.

Ⅶ:Common CNC Machining Defects & PRIME’s Prevention Strateg

CNC machining involves high-precision processes where even minor issues can affect functionality or assembly. At PRIME, we implement advanced programming, rigorous inspections, and strict process controls to minimize defects and ensure consistent quality.

1. Tool Marks & Surface Inconsistencies

Description: Visible lines or rough areas caused by worn tools, incorrect feed rates, or toolpath overlaps.

PRIME Solution: Real-time tool wear monitoring, optimized feed/speed programming, and post-process polishing for consistent finishes.

2. Dimensional Out-of-Tolerance

Description: Finished parts deviate from specified dimensions due to thermal expansion, machine inaccuracy, or clamping distortion.

PRIME Solution: High-precision 5-axis CNCs, calibrated probes, and full CMM validation to maintain tolerances within ±0.005mm.

3. Burrs & Sharp Edges

Description: Unwanted metal protrusions formed during drilling, milling, or slotting operations.

PRIME Solution: Deburring via ultrasonic, brush, or laser methods ensures edge safety and assembly fit below 0.01mm.

4. Chatter & Vibration Marks

Description: Surface waves or irregular cuts caused by unstable tooling, machine resonance, or poor fixturing.

PRIME Solution: Rigid fixturing, dampened tooling systems, and dynamic spindle speed control eliminate vibration artifacts.

5. Misalignment in Multi-Side Machining

Description: Inaccurate alignment between faces during repositioning or when switching between machines.

PRIME Solution: Custom jigs, rotary tables, and in-process probing allow consistent datum control across all faces.

Ⅷ:Diverse Applications: The Impact of PRIME CNC Machined Parts

CNC machined components are vital across high-performance industries. Their precision, repeatability, and material versatility make them ideal for applications requiring tight tolerances and long-term reliability. At PRIME, we deliver custom-machined parts that align with your sector’s specific engineering standards and end-use functionality.

1. Automotive Industry

Impact: Demands high-performance, engine-ready parts with tight tolerances.

PRIME’s Role: We supply CNC-turned shafts, engine housings, transmission casings, and cooling system components with ISO/TS compliance.

2. New Energy & EV Industry

Impact: Requires compact thermal solutions and vibration-resistant structures.

PRIME’s Role: We machine cooling plates, battery cases, and inverter frames from high-conductivity aluminum, ensuring flatness, fluid flow control, and lifecycle durability.

3. Medical & Biotechnology

Impact: Requires biocompatibility, precision edges, and surface cleanliness.

PRIME’s Role: We deliver titanium and stainless-steel surgical tools, implant housings, and lab fixtures with Ra < 0.4 μm and full traceability.

4. Marine & Offshore Engineering

Impact: Components must resist saltwater, pressure, and temperature changes.

PRIME’s Role: We supply 316L and duplex steel parts for underwater pumps, shafts, and flanges with anti-corrosion coatings and CMM verification.

5. Precision Instrumentation

Impact: Tolerance-sensitive components critical to scientific accuracy.

PRIME’s Role: Ultra-precise parts in brass, POM, and aluminum for lab equipment, calibration devices, and micrometer systems with ±0.002 mm accuracy.

6. Industrial Machinery & Tooling

Impact: Involves high-load, wear-resistant parts for continuous operation.

PRIME’s Role: Hardened steel cams, bushings, gears, and fixture plates machined to exacting specs with post-treatment options available.

From EV cooling systems to marine connectors — PRIME delivers tailored CNC solutions that drive your industry's performance and reliability.

Have a specialized requirement? Share your technical drawings with us and our engineers will recommend the best CNC approach for your application.

Discuss Your ApplicationⅨ:How to Choose the Right CNC Parts Supplier

Choosing the right CNC parts supplier is more than just comparing prices. It’s a strategic decision that directly impacts your product precision, project timeline, and long-term cost-efficiency. Below are the 6 most critical factors to evaluate before partnering with a CNC machining supplier.

1. Technical Capabilities & Equipment

- Do they operate 3-axis, 4-axis, or 5-axis machines for complex geometries?

- Are the machines modern, calibrated, and automation-supported?

- Can they handle your required materials: aluminum, stainless steel, titanium, brass, plastics?

🛠 Tip: Ask for machining tolerances and surface finish examples (e.g., ±0.005mm, Ra0.8).

2. Quality Control & Certifications

- Is the supplier certified to ISO 9001, IATF 16949, or AS9100 (for aerospace)?

- Do they use CMMs , optical scanners, or SPC systems for inspection?

- Are they capable of providing FAI, PPAP , or full traceability documents?

🔍 Tip: Ask to review past inspection reports and quality control logs.

3. Experience with Complex Parts

- Have they worked with tight-tolerance, multi-operation, or assembly-ready parts?

- Do they understand DFM (Design for Manufacturability) for CNC parts?

- Can they handle high-mix/low-volume or mass production?

🏆 Tip: Check if they have relevant experience in your industry: automotive, robotics, medical, etc.

4. Production Capacity & Scalability

- How many machines and shifts do they run?

- Can they ramp up production quickly for new orders?

- What is their average lead time from order to delivery?

⚙️ Tip: Look for real factory photos, machine lists, and actual throughput data.

5. Communication & Engineering Support

- Do they respond promptly and professionally to RFQs and drawings?

- Is there a dedicated engineer or project manager assigned to you?

- Do they offer design consultation or DFM improvements?

💬 Tip: Clear and timely communication avoids costly mistakes.

6. Packaging, Logistics & Location

- Do they provide secure packaging to prevent scratches or deformation?

- Are they export-experienced, handling customs documents and labeling?

- Can they offer both air express and sea freight solutions?

🚚 Tip: Consider their time zone, delivery speed, and logistics support.

At PRIME, we meet and exceed these standards. With over 30 years of experience, ISO-certified production, and 10 precision CNC lines, we are trusted by engineers and procurement teams worldwide.

Ⅹ:Design for Manufacturability (DFM) in CNC Machining

Maximize precision, reduce costs, and accelerate production with expert DFM support tailored for custom CNC parts.

What is DFM? Design for Manufacturability (DFM) in CNC machining is a strategic engineering practice that optimizes part designs to simplify machining, reduce time and material waste, and improve quality — all before production begins.

At PRIME, our DFM services work as an extension of your engineering team. We make sure your CNC parts are not only functional, but also optimized for efficiency, precision, and repeatability in manufacturing.

Buyer's pain: “My part has tight tolerances and complex features. I'm worried about high machining time, scrap, and expensive rework. How can I ensure my design is CNC-friendly?”

1. Early Review & Feasibility Check

We analyze your 2D drawings and 3D CAD models to flag potential issues such as undercuts, deep cavities, or excessive tolerance zones — before any chips are cut.

2. Material Selection & Cost Efficiency

- Material Suitability: Recommendations based on machinability, strength, and finish requirements.

- Optimized Stock Sizes: Match raw material stock to reduce waste and machining time.

- Cost-Effective Grades: Substitute high-cost alloys with alternatives that still meet performance needs.

3. Geometry Simplification & Cycle Time Reduction

- Feature Redesign: Simplify pockets, wall thickness, or fillets to reduce tool changes.

- Setup Optimization: Design parts for fewer repositions and faster clamping.

- Toolpath Efficiency: Improve paths for faster machining and longer tool life.

4. Tolerance Management & Machinability Enhancement

- Fit-for-Function Tolerances: Only apply tight tolerances where necessary.

- Surface Finish Optimization: Balance aesthetics, cost, and time.

- Defect Prevention: Avoid chatter, tool marks, or burrs through design foresight.

Our CNC DFM service is not just a consultation — it's a competitive advantage. By collaborating early with our experienced engineers, you unlock smarter part designs that are easier, faster, and more affordable to produce.

Cut costs. Improve manufacturability. Bring precision parts to market faster.

Ⅺ:Metal Stamping vs. CNC Machining: Choosing the Right Manufacturing Process

When sourcing metal components, B2B buyers often face a key decision: should they choose metal stamping or machining? Both are efficient manufacturing methods with unique advantages in cost, precision, volume, and material usage. At PRIME, we offer both stamping and CNC machining capabilities, enabling us to provide objective guidance and the best solution for your specific needs.

Metal Stamping: Ideal for High-Volume, Cost-Effective Production

Metal stamping is a cold-forming process that uses dies and presses to shape flat metal into desired forms. It's a highly efficient method for mass production.

- Cost-effectiveness at scale: Once tooling is made, part costs drop significantly for large runs.

- Speed & efficiency: Stamping presses can produce parts within seconds, especially with progressive dies.

- Material utilization: Less waste compared to subtractive machining.

- Consistency: Fixed tooling ensures repeatable, reliable quality for large batches.

- 2D geometry: Ideal for flat parts with bends, holes, and complex profiles.

Best Applications:

Automotive brackets and panels, electronic housings, appliance components, medical trays and enclosures, HVAC parts.

CNC Machining: Perfect for Low Volume, High Precision, 3D Parts

CNC machining is a subtractive process that removes material from solid blocks to form precise parts. It’s highly flexible and accurate.

- Precision: Achieves tight tolerances and complex 3D shapes not possible with stamping.

- Material range: Suitable for hard metals, plastics, and thick stock materials.

- Low-volume efficiency: Ideal for custom parts or prototypes without expensive tooling.

- Design flexibility: Easy to update via software without physical die changes.

- Surface finish: Produces smooth surfaces with minimal post-processing needed.

Best Applications:

Aerospace components, medical implants, precision custom parts, prototypes, and parts with internal passages.

Comparison Table: Stamping vs. CNC Machining

| Feature | Metal Stamping | CNC Machining |

|---|---|---|

| Production Volume | High to ultra-high | Low to medium |

| Part Complexity | 2D profiles and bends | Complex 3D geometries |

| Tooling Cost | High (dies) | Low (programming) |

| Unit Cost | Very low (at scale) | Higher |

| Lead Time | Longer (for dies) | Shorter (for setup) |

| Material Thickness | Thin sheet metal | Wider range |

| Tolerance | ±0.01mm | ±0.005mm |

PRIME’s Integrated Approach

At PRIME, we don’t just offer one solution. With expertise in both precision metal stamping and CNC machining, we evaluate your project objectively and recommend the most cost-effective and technically suitable method.

Share your project details with us, and our engineering team will help you choose the best manufacturing path.

Ⅻ:Global Supply Chain & Logistics: Seamless Worldwide Delivery

For international B2B buyers, efficient and reliable logistics are just as important as product quality. With rich global trade experience and a robust supply chain network, Prime ensures your CNC parts are delivered seamlessly, on time, and within budget — wherever you are.

Buyer Concern

“How can I ensure my parts arrive on time without unexpected customs delays or hidden costs when working with international suppliers?”

Prime’s End-to-End Logistics Solution

Prime's commitment goes far beyond manufacturing. We provide intelligent logistics and supply chain support to eliminate sourcing friction and boost your global competitiveness. Here’s how we deliver peace of mind and precise parts — anywhere on the map.

1. Trade Compliance & Export Expertise

- HS Code Classification: Ensures correct tariff application and minimizes customs delays.

- Comprehensive Documentation: Including invoice, packing list, certificate of origin, and destination-specific forms.

- Up-to-date Compliance: We track evolving export laws and sanctions so your delivery stays uninterrupted.

2. Flexible Transport Strategies

Our global logistics partnerships ensure optimal routing:

- Air Freight: Fast, secure delivery for urgent and high-value orders.

- Ocean Freight (FCL/LCL): Best for bulk and cost-efficiency.

- Multimodal Options: Blending speed and budget using air-sea-land combinations.

3. Real-Time Tracking & Proactive Communication

Transparency is key. From factory to your doorstep, you’ll get real-time updates. We alert you to potential delays before they become issues.

4. Secure Packaging & Damage Control

- Custom-Fit Packaging: Designed for secure transit.

- VCI & Anti-Corrosion Materials: Protects precision metal components during storage and shipment.

- Impact Absorption: Prevents transit damage with protective cushioning.

5. Global Warehousing & Inventory Buffering

For recurring buyers and long-term contracts, we offer regional warehousing and JIT inventory options — reduce lead times, smooth out supply fluctuations, and ensure business continuity.

The Prime Logistics Advantage

Let Prime handle logistics, compliance, and delivery while you focus on growth. We bring your components where you need them — on time, every time.

XIII: PRIME CNC R&D & Innovation – Empowering Custom Precision

In the world of custom CNC machining, innovation is more than an advantage—it's a necessity. For B2B buyers, partnering with a forward-thinking manufacturer ensures not just today’s success, but tomorrow’s breakthroughs. At PRIME, our dedicated R&D team focuses on material evolution, machining excellence, and next-gen digital integration to deliver high-precision, cost-effective, and future-ready CNC solutions.

Buyer Concern: Will this supplier adapt to new materials, complex geometries, and evolving tolerances? Can they keep up with my next-generation product requirements?

1. CNC Material Innovation

We explore advanced metals and plastics—including titanium, Inconel, PEEK, and carbon fiber composites—to meet the demanding requirements of aerospace, medical, and EV sectors. Our team collaborates with research institutes to validate performance under real-world stress, corrosion, and thermal scenarios.

2. Process Intelligence & Automation

- Digital Twin Simulation: Virtually test toolpaths and predict part behavior before production.

- AI-Assisted CAM Programming: Adaptive tool pathing based on real-time learning.

- Robotic CNC Cells: Fully integrated automation for multi-shift operations.

3. Environmental Sustainability

Our green CNC initiatives reduce scrap and energy usage, supporting clients’ ESG goals. Strategies include:

- Coolant Recycling Systems

- Energy-Optimized Spindle Control

- Waste Stream Tracking for better material recovery

4. Application-Driven Customization

Whether you're launching a new product line or need an ultra-precise prototype, PRIME's R&D team works hand-in-hand with your engineers. From DFM consulting to small-batch preproduction, we transform concepts into precision-machined reality with speed and agility.

Why PRIME for CNC Innovation?

Our CNC R&D is not just about machines—it’s about enabling your innovation pipeline. PRIME offers a unique blend of engineering foresight, material mastery, and agile manufacturing that empowers your team to move fast, scale smart, and stay competitive.

Contact Our EngineersXIV: Value-Added CNC Services – From Machining to Market

In today's competitive B2B landscape, simplifying your supply chain is more than convenience—it’s a strategy. PRIME provides a comprehensive suite of value-added CNC services that help you eliminate vendor complexity, reduce cost, and accelerate time to market.

Buyer Concern

“I need more than just CNC-machined parts—I need heat treatment, coating, assembly, and logistics support. Can one supplier take care of it all with quality and speed?”

PRIME’s Integrated CNC Support

As a vertically integrated partner, PRIME offers tailored post-processing, packaging, and subassembly services alongside our core CNC machining. This streamlines your operations and provides consistent, ready-to-use components—backed by our strict ISO-compliant quality standards.

1. Precision Secondary Operations

- Tight-Tolerance CNC Machining: Achieving micron-level precision on complex geometries.

- Threading, Reaming, Milling: Advanced subtractive processes for precision mating components.

- Surface Grinding: Flatness and finish refinement for sealing or alignment surfaces.

2. Mechanical Assembly & Integration

- Subassembly: Screws, bushings, inserts, or combining multiple CNC parts.

- Welding: MIG/TIG welding for structural integrity in finished modules.

- Precision Fit Verification: Ensuring alignment, flatness, and torque specs are met.

3. Surface Finishing & Treatments

- Anodizing & Powder Coating: For protection and aesthetics.

- Electroplating: Zinc, nickel, or chrome plating for corrosion and wear resistance.

- Shot Peening & Polishing: Improving fatigue strength or cosmetic appearance.

4. Heat Treatment & Metallurgical Services

- Hardening & Tempering: For durability and mechanical strength.

- Annealing: Improving formability and stress relief.

- Vacuum or Controlled Atmosphere Furnaces: Ensuring repeatable metallurgical results.

5. Precision Cleaning & Edge Finishing

- Ultrasonic Cleaning: Removal of oils and particles for cleanroom applications.

- Deburring & Edge Breaking: Via tumbling, brush deburring, or CNC edge rounding.

- Laser Deburring: For complex internal geometries.

6. Custom Kitting & Industrial Packaging

- Component Kitting: Assembling all parts needed for production or installation.

- Protective Packaging: Anti-corrosion wraps, foam inserts, or anti-static bags.

- Labeling & QR Coding: Traceability and inventory optimization at your site.

Your End-to-End CNC Partner

PRIME isn’t just a machine shop—we're your strategic manufacturing partner. Our holistic CNC solutions reduce touchpoints, accelerate delivery, and improve consistency across the product lifecycle.

From material sourcing to shipping-ready kits, we help you build smarter, faster, and leaner.

CNC-Compatible Materials

| Aluminum (6061, 7075) | Stainless Steel (304, 316) |

| Brass & Copper | Carbon Steel |

| Titanium | Tool Steel |

| PEEK / Delrin | Nylon / Acrylic |

Surface Finishing

| Anodizing (Type II, III) | Powder Coating |

| Bead Blasting | Polishing / Brushing |

| Black Oxide | Laser Etching |

| Zinc / Nickel Plating | Passivation |

XV: More About Custom CNC Machining

Explore our end-to-end CNC capabilities, precision tolerances, and scalable production support tailored for your high-performance components.

Machining Capabilities

- 3-Axis / 4-Axis / 5-Axis CNC Milling

- Precision CNC Turning (Lathe)

- Swiss Turning for Small Parts

- Live Tooling & Multi-Tasking

- Wire EDM / Sink EDM

- Rapid Prototyping to Mass Production

In Summary

Choosing the right CNC machining partner isn’t just about price—it’s about precision, consistency, and partnership. This guide has covered everything from materials and tolerance control to production scalability and global logistics. Your success depends on a supplier who not only meets today’s technical needs but also empowers future innovation.

Key Insights for CNC Buyers

- Precision is Everything: Your CNC supplier must consistently achieve tight tolerances, surface finishes, and dimensional accuracy—no compromises.

- Versatility Matters: Look for experience across materials like aluminum, stainless steel, titanium, and technical plastics to support evolving design needs.

- Quality Systems Count: ISO-certified processes, real-time SPC, and in-house inspection equipment are essential for reliability and compliance.

- Agility & Communication: From prototyping to large-batch production, choose a partner that’s responsive and offers engineering support along the way.

- Global Reach, Local Precision: Seamless export capability, efficient logistics, and regional service make international collaboration easy and efficient.

Why PRIME is Your CNC Partner

With over 30 years of experience, PRIME combines legacy precision with modern automation. Our 5-axis capabilities, material diversity, and digital quality systems support everything from prototypes to global production runs—without compromising performance.

We don’t just machine parts—we help you optimize cost, improve manufacturability, and bring complex designs to life with precision and speed.

Global Scale, Precision Delivered

From automotive and aerospace to medical and energy industries, PRIME supports OEMs and B2B buyers worldwide. Our export-ready logistics team ensures compliant, on-time delivery to North America, Europe, the Middle East, and beyond.

Partner with a supplier that understands not just production—but precision, documentation, and delivery at scale.

Let’s Build Better, Together

Whether you're sourcing high-tolerance CNC components or optimizing your current supply chain, PRIME is ready to help. Upload your drawings through our secure portal, and receive a detailed feasibility report and competitive quote within 24 hours.

Discover why global OEMs trust PRIME to deliver precision without compromise.

Get a CNC QuoteJust a Few of the Partners Who Trust Our Quality

*Logos are property of their respective owners.

What Our Customers Say

Real feedback from global buyers who trust us to deliver high-quality, customized industrial components.

Harry M., New York

Purchasing Manager – Metal Components

We’ve sourced CNC machined parts from Prime for over two years. The precision is consistently excellent, tolerances are spot on, and their team is responsive and professional. Fast lead times and secure packaging make them a reliable long-term partner.

Robert J., California

Strategic Sourcing Specialist – Industrial Hardware

The forged components we received from Prime were top quality — strong material integrity, accurate dimensions, and zero defects. Their team understood our specs clearly and delivered right on schedule. Great supplier for high-stress applications.

Emily T., Texas

Supply Chain Buyer – Custom Metal Parts

We ordered a batch of custom metal welded assemblies from Prime, and the quality was outstanding. The welds were clean, uniform, and met all our strength requirements. Communication was smooth, and delivery was faster than expected.

Hannah K., Ontario

Senior Buyer – Automotive

Prime supplies us with custom metal casting parts that meet strict automotive standards. Their ISO-certified quality, fast prototyping, and on-time delivery make them a trusted partner in our supply chain.

Luis R., Barcelona

Procurement Lead – Electronics

Prime has been a reliable partner for our custom plastic parts in consumer electronics. The injection-molded components are precise, durable, and always delivered on time, helping us stay competitive in the market.

Nadia P., Dubai

Category Manager – Industrial Projects

Prime delivers high-quality custom metal forgings for our industrial machinery. The parts are strong, reliable, and meet our exact specifications. With consistent quality and on-time delivery, Prime has become a trusted partner in our long-term projects.

Jon S., Munich

Operations Buyer – Machinery

Prime’s custom metal fasteners have proven to be durable and precise, perfectly fitting our heavy-duty machinery. Their consistent quality and reliable delivery help us maintain smooth production with fewer interruptions. Prime is a supplier we can count on for critical components.

Aisha M., Sydney

Sourcing Manager – Energy

From quoting to final inspection, Prime stayed on schedule with transparent updates. Their QC reports, salt spray results, and traceability made onboarding very smooth.

Get Your Custom Solution & Quote

REPLY WITHIN 24 HOURS

Start a Conversation with Our Experts

When you contact us, you get more than just a price. You get a dedicated partner.

- ✔ 30+ Years of Manufacturing Excellence, Direct from Our Factory

- ✔ Custom-Engineered Solutions for Your Needs

- ✔ Global Shipping & Logistics Support

- ✔ A Transparent, No-Obligation Quote

- ✔ 100% Confidentiality Guaranteed

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!