Precision Metal Casting Solutions For The Global Industry

Prime---Your Trusted Factory Since 1993

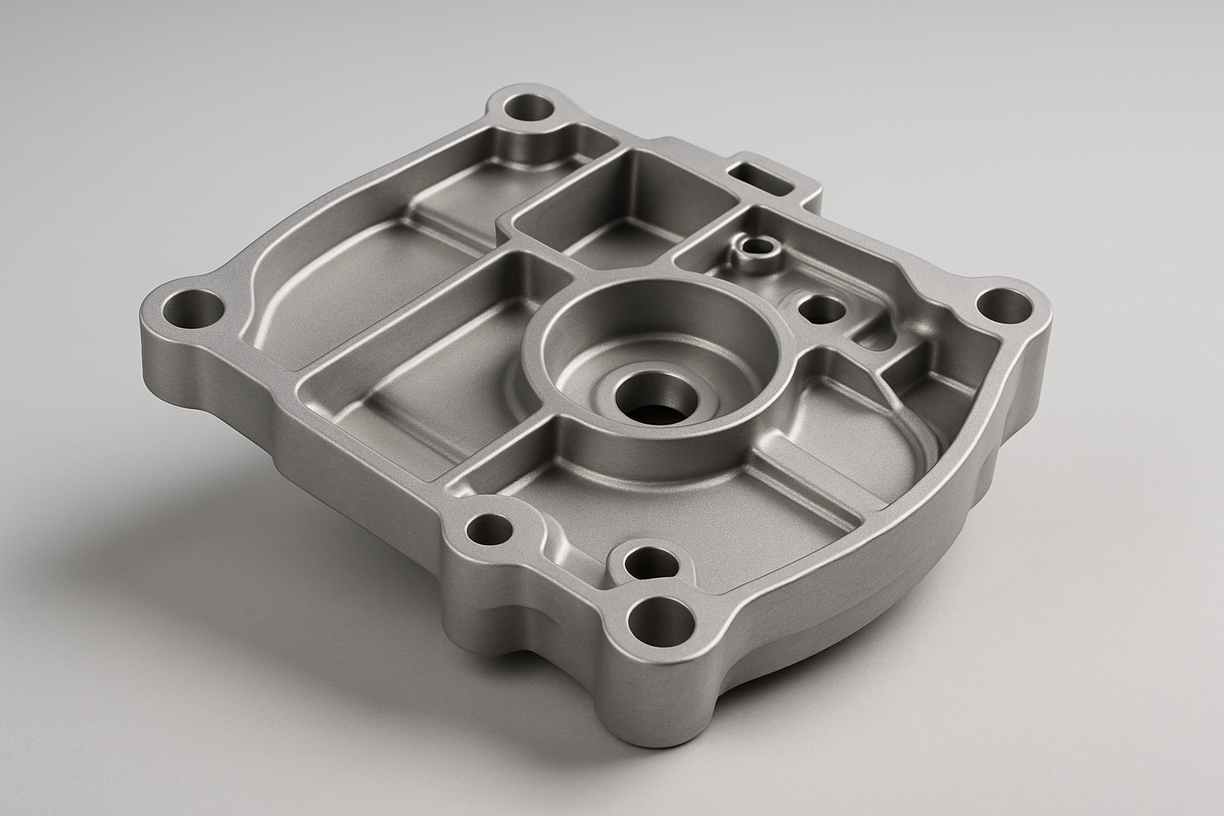

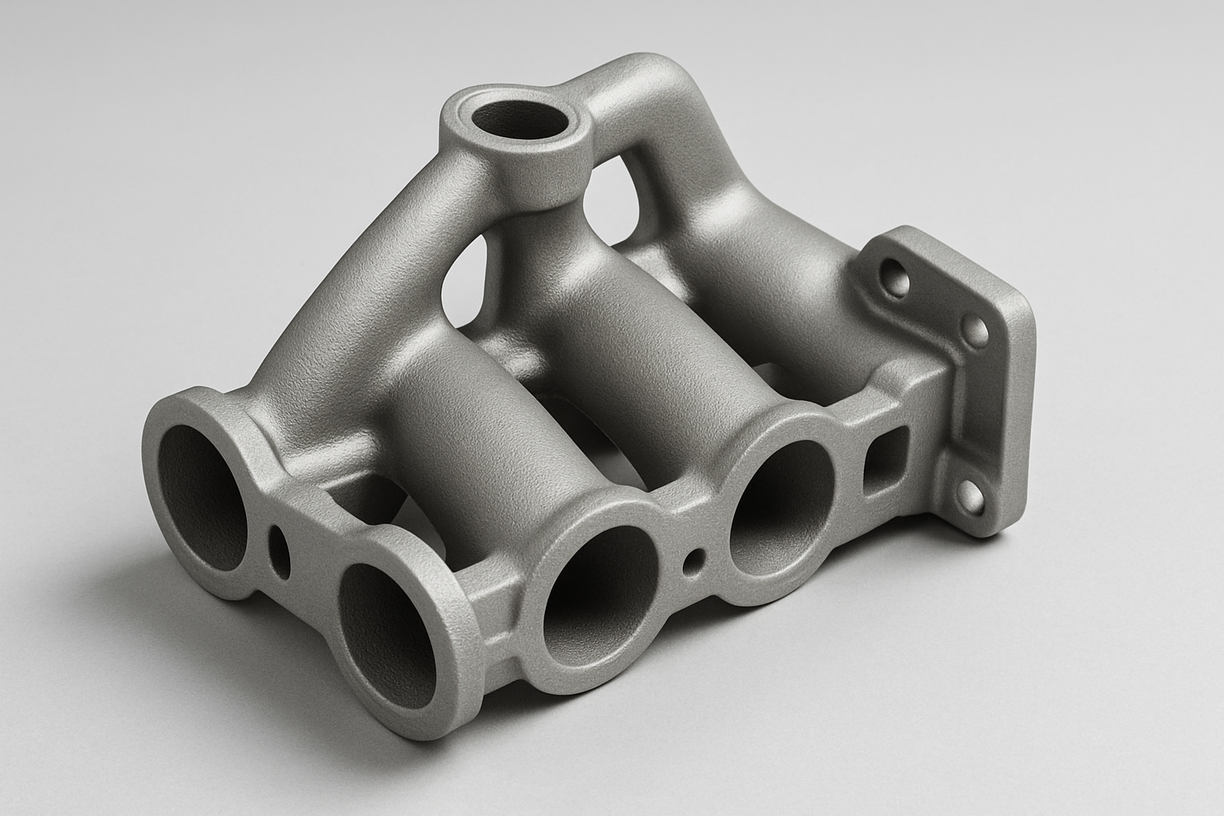

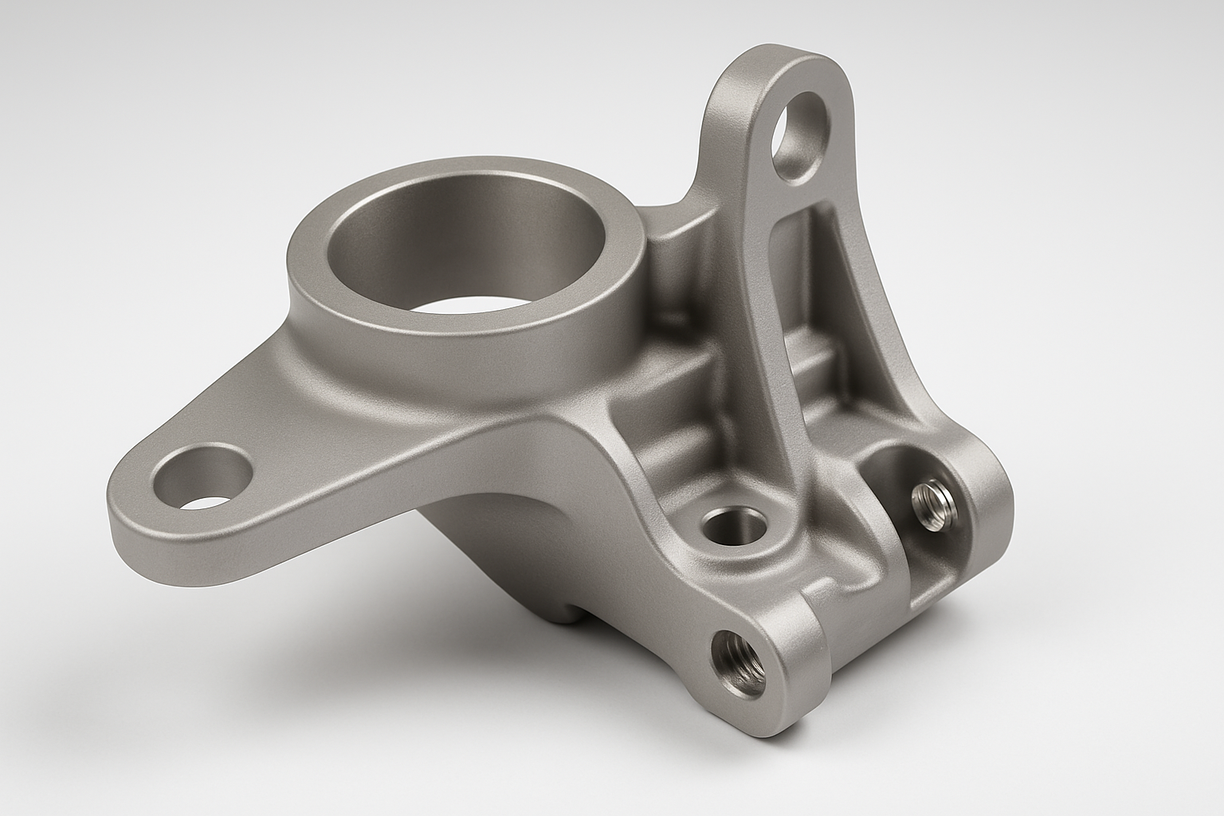

Common Products Of Metal Casting

Prime offers a full range of high quality metal casting parts for a wide range of industrial, mechanical and manufacturing scenarios.

Sand Casting

Sand casting is a traditional process of producing metal parts by sand mold, which is suitable for castings with large or complex structure. The method has high flexibility and is suitable for small batch and multi-variety customization.

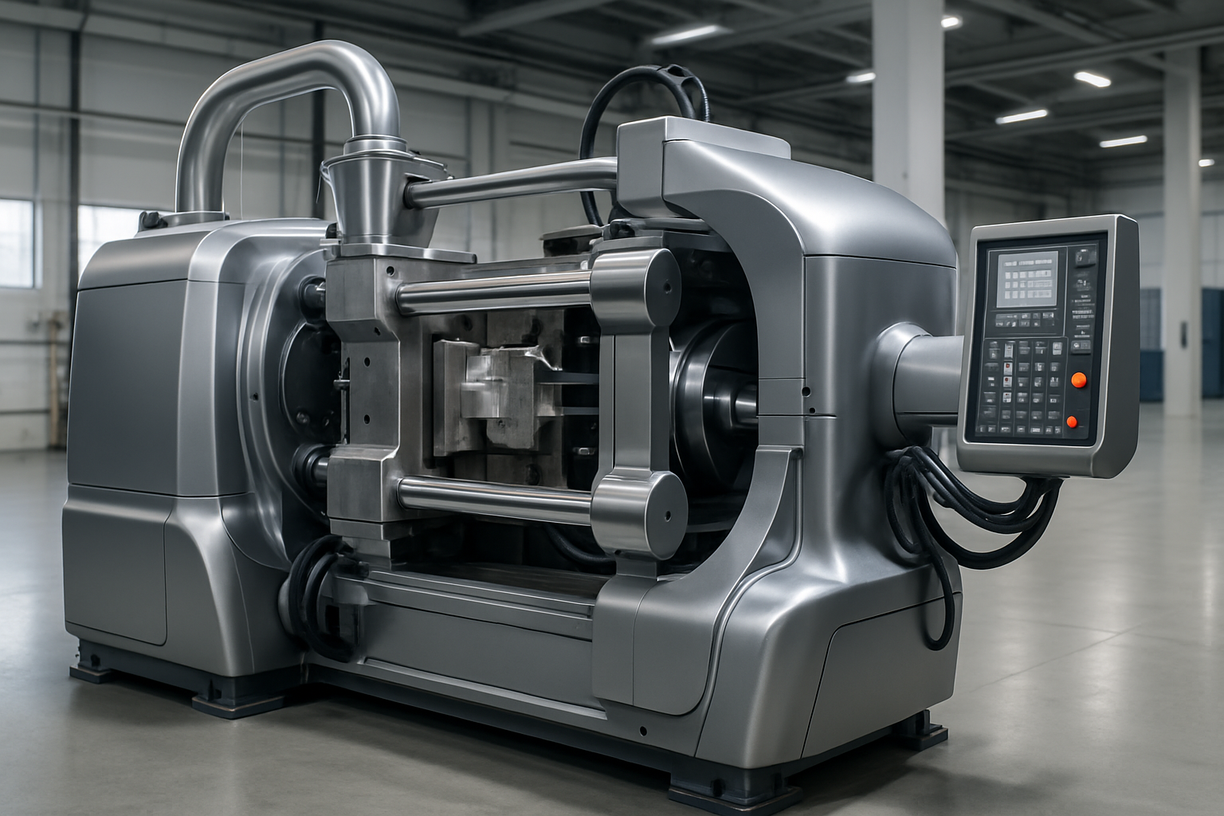

Die Casting

Die casting is a high-pressure injection of liquid metal into metal molds for efficient mass production. The utility model is suitable for manufacturing small and medium-sized metal parts with high dimensional accuracy and smooth surface.

Lost Foam Casting

The Lost-foam casting die is a foam mould that disappears in the liquid metal, enabling one-off castings of complex shapes. Especially suitable for complex structure, a number of cavity of large parts.

Investment Casting

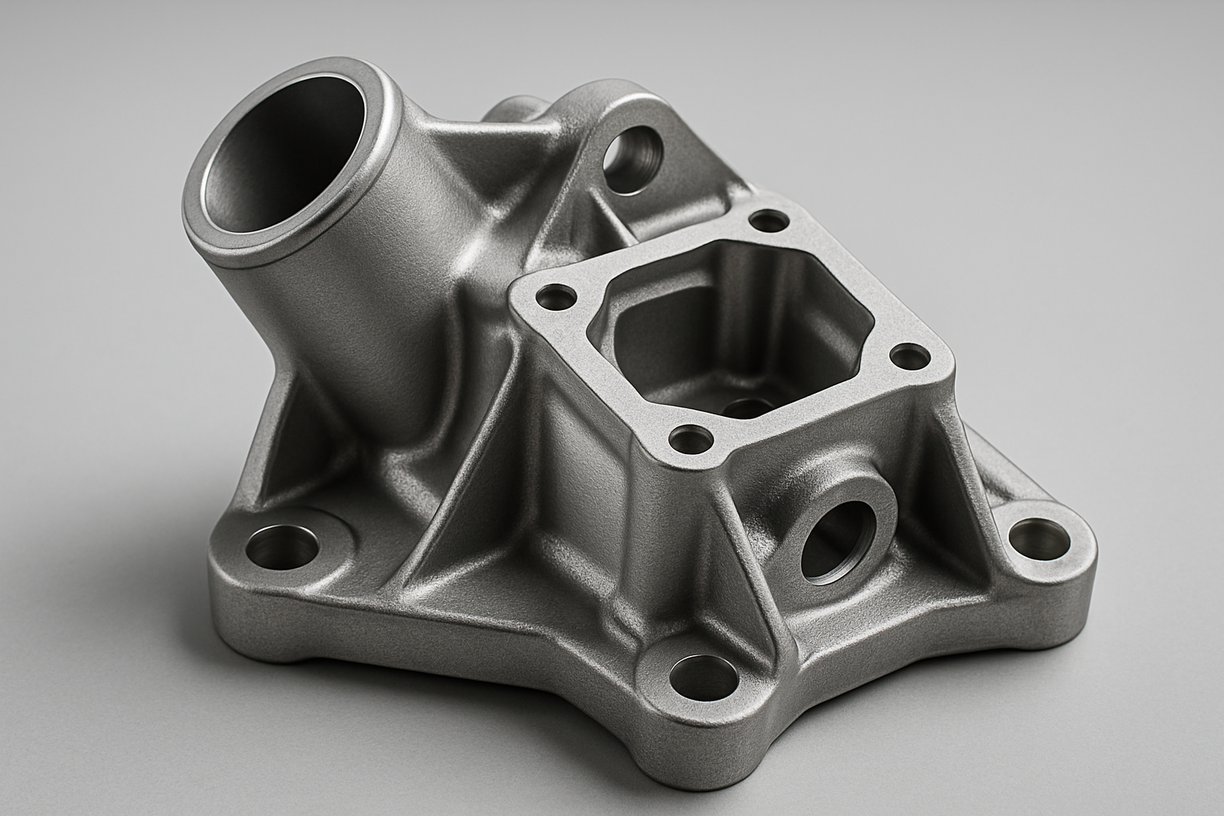

Precision casting, also known as lost wax casting, can produce small metal parts with smooth surface and fine structure. The process is well suited for parts that require high precision and complexity.

Centrifugal Casting

Centrifugal casting uses a high-speed rotating mold to fling liquid metal toward the mold wall to form a casting. It is mainly used for manufacturing hollow cylindrical parts such as pipes and sleeves with excellent compactness.

Low Pressure Casting

Low-pressure casting uses low-pressure gas to inject liquid metal into the mold slowly to ensure uniform filling. It is suitable for the production of high strength and Non-ferrous metal castings such as automobile wheel hubs.

Why Choose PRIME: Strategic Advantages in Metal Casting Supply

Choosing the right metal casting supplier is a strategic decision that directly impacts project success, product quality, and supply chain efficiency. At PRIME, we stand out through decades of expertise, advanced technology, uncompromising quality commitment, and a customer-first approach. With our proven experience, scalable manufacturing, precision assurance, and global logistics, PRIME is the trusted partner for all your casting needs.

- 30+ Years of Proven Expertise: Established in 1993, our deep industry knowledge empowers us to tackle complex challenges and deliver consistent excellence.

- ISO 9001:2015 Certified Quality: Our entire process—from material sourcing to final inspection—follows rigorous international standards to ensure reliable output.

- 15 Advanced Production Lines: Our high-speed infrastructure handles large orders with agility and scale, keeping your production timeline intact.

- Global Reach, Local Support: With exports to North America, Europe, the Middle East, and Australia, we ensure seamless international delivery and customs expertise.

- One-Stop Capabilities: Our comprehensive offering includes CNC parts, welded assemblies, castings, and fasteners—streamlining your supply chain with integrated solutions.

Ready to Experience the PRIME Difference?

Upload your drawings and specifications via our secure portal, and our engineering team will provide a full feasibility review and competitive quote within 24 hours.

Let’s build something extraordinary together.

Address Your Concerns: FAQ about casting parts

To further assist our customers and provide comprehensive information, we have compiled a list of frequently asked questions about casting parts and our services. Our goal is to solve common problems and provide clear, concise answers that will give you knowledge and confidence in your purchasing decisions, directly addressing the pain points of poor communication and lack of clarity.

What types of metal casting processes do you offer?

We offer a wide range of casting processes, including sand casting, die casting, investment casting and gravity casting. We will select the appropriate casting process according to your product requirements, material specifications and order quantity.

Can you provide custom castings according to our drawings?

Yes, we specialize in producing custom castings according to your drawings or samples. Our engineering team will review your requirements and provide technical support throughout the project.

What materials do you have for your castings?

We offer castings in a variety of materials, including aluminum, iron, steel, brass and other alloys. Material selection depends on your application and performance requirements.

What quality control measures do you implement?

Our factory is ISO certified and performs rigorous quality inspections at every stage, including raw material testing, dimensional inspection, and final product inspection. We can also provide third-party inspection services according to customer needs.

How do you ensure the consistency and accuracy of castings?

We use advanced production equipment, skilled technical personnel and standardized process to ensure that each batch of castings meet the required tolerances and quality standards.

Can you assist in product design or optimization?

Of course. Our engineering team can assist you with product design, manufacturing process optimization and cost reduction to ensure that your parts are both functional and economical.

Our Factory Insight

- Ⅰ:What is a metal casting part?

- Ⅱ:Reveal Casting Parts And Our Processes

- Ⅲ:Material Selection Guide: The Foundation of Performance

- Ⅳ:Surface Treatment Options: Enhance Durability and Aesthetics

- Ⅴ:Precision mould manufacturing: A key step to determine the quality of casting

- Ⅵ:Our Commitment to Quality

- Ⅶ:Common Casting Defects & PRIME’s Prevention Strategy

- Ⅷ:Diverse applications: the impact of PRIME casting components

- Ⅸ:How to Choose the Right Casting Parts Supplier

- Ⅹ:Esign for Manufacturability (DFM)

- Ⅺ:Metal Casting vs. CNC Machining: Choosing the Right Manufacturing Process

- Ⅻ:Global Supply Chain & Logistics: Seamless Worldwide Delivery

- XIII:PRIME R&D and Innovation — Advancing Metal Casting Technology

- XIV:Value-Added Services — Beyond Casting, Toward Complete Solutions

- XV:More informati

Ⅰ:What is a metal casting part?

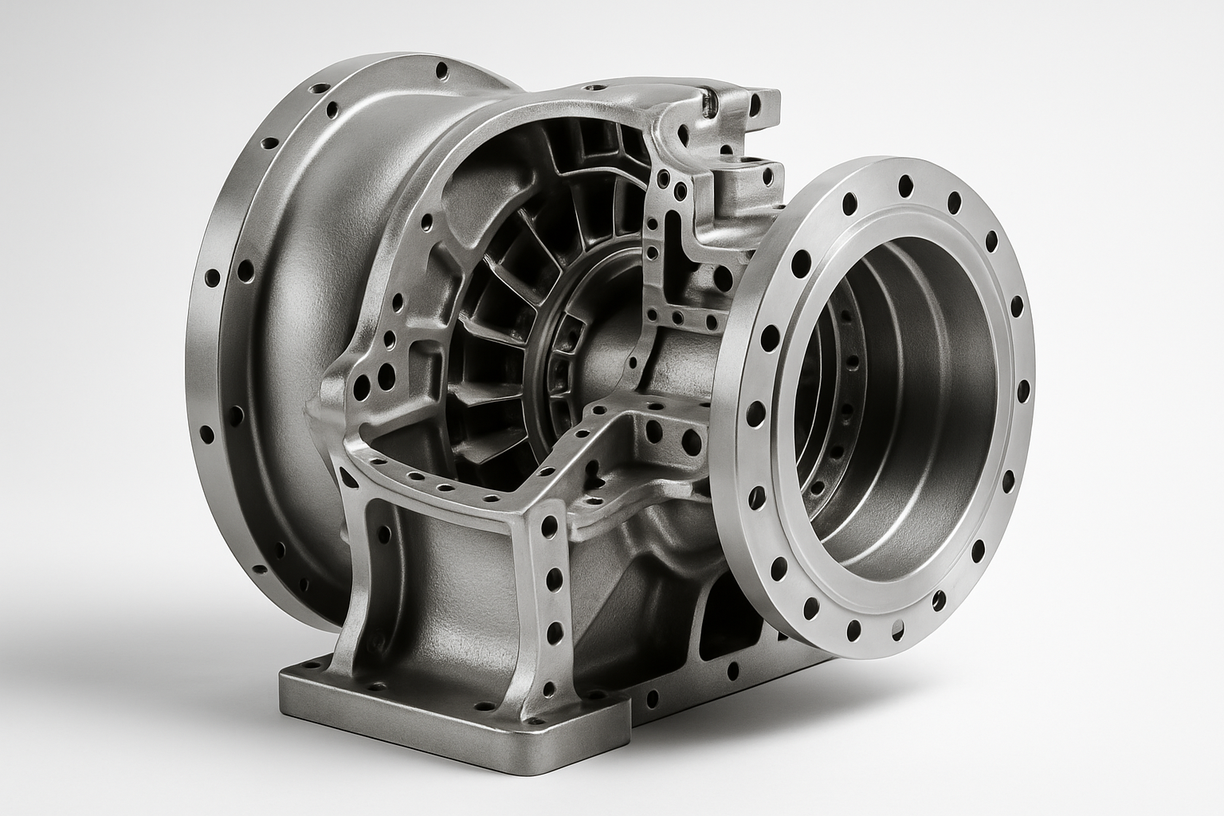

Metal casting parts are precision-engineered components produced by pouring molten metal into a mold cavity where it solidifies into the desired shape. This process allows for the creation of complex geometries and robust structures. Depending on the application, various casting methods such as sand casting, die casting, investment casting, and gravity casting are used. Casting is ideal for manufacturing large, heavy, or intricate parts that require strength and durability.

Metal casting is a highly efficient manufacturing method for producing complex and durable metal components, especially in medium to large volumes. It offers excellent design flexibility, material utilization, and the ability to form intricate internal structures. Widely used in industries such as automotive, aerospace, machinery, energy, and heavy equipment, casting is ideal for parts requiring strength, stability, and complex shapes.

Key Characteristics of Metal Casting Parts

• Integrated forming of complex structure

Metal casting can integrate multiple parts into a whole structure and reduce the assembly process. It is suitable for designing complex or irregular parts, such as pump body, valve shell, engine shell, etc. .

• Extensive material compatibility

Applicable to a variety of metals and alloys (such as gray iron, ductile iron, aluminum alloy, copper alloy, stainless steel, etc.) , according to the performance requirements of flexible material selection, meet the strength, corrosion resistance, thermal conductivity and other different application scenarios.

• Good dimensional stability and repeatability

Die casting process (such as die casting, precision casting) with high precision and consistency, suitable for mass production of standard parts, can achieve ± 0.1 mm or higher precision.

• Variable surface quality

Depending on the process, different grades of surface quality can be achieved from rough (sand casting Ra 12.5 μm) to relatively smooth (precision casting Ra 3.2 μm) . The appearance and corrosion resistance can be further improved by sandblasting, electroplating, painting, etc. .

Common Types of Metal Casting Operations

- Sand Casting: The most widely used conventional casting method is suitable for single-piece, small batch and large complex structural parts.

- Investment Casting/Lost Wax Casting: Small parts with complex details and high Surface finish can be produced.

- Die Casting: High pressure injection of molten metal into metal molds for mass production.

- Low Pressure Casting: Low pressure is used to force the molten metal from the crucible into the mold for more precise control.

- Centrifugal Casting: The metal is distributed on the inner wall of the die by centrifugal force generated by high-speed rotation.

- Shell Molding: The resin coated sand mold was used in the improved sand mold casting.

Industries That Rely on Metal Casting

• The auto industry

Castings provide complex geometry and high strength performance, which is the key link of lightweight and cost control.

• Heavy Machinery and engineering equipment

High structural strength, strong wear resistance, suitable for high load conditions.

• Agricultural Machinery

Strong durability, adapt to the harsh outdoor environment, suitable for long-term use.

• Railway and rail transit

Can withstand strong impact load, with high stability and safety.

• Energy and power industry

To meet the requirements of high temperature, high pressure, high load operating environment.

Ⅱ:Reveal Casting Parts And Our Processes

Whether you are buying castings for the first time or you want to know more, this section will help you gain a comprehensive understanding of the Metal Casting field and how Prime can ensure your project delivery. We will introduce the core issues, explain key processes, and highlight how our solutions accurately address the challenges common to industrial buyers. Our goal is to provide you with practical knowledge to help you make informed decisions and advance your purchasing with confidence.

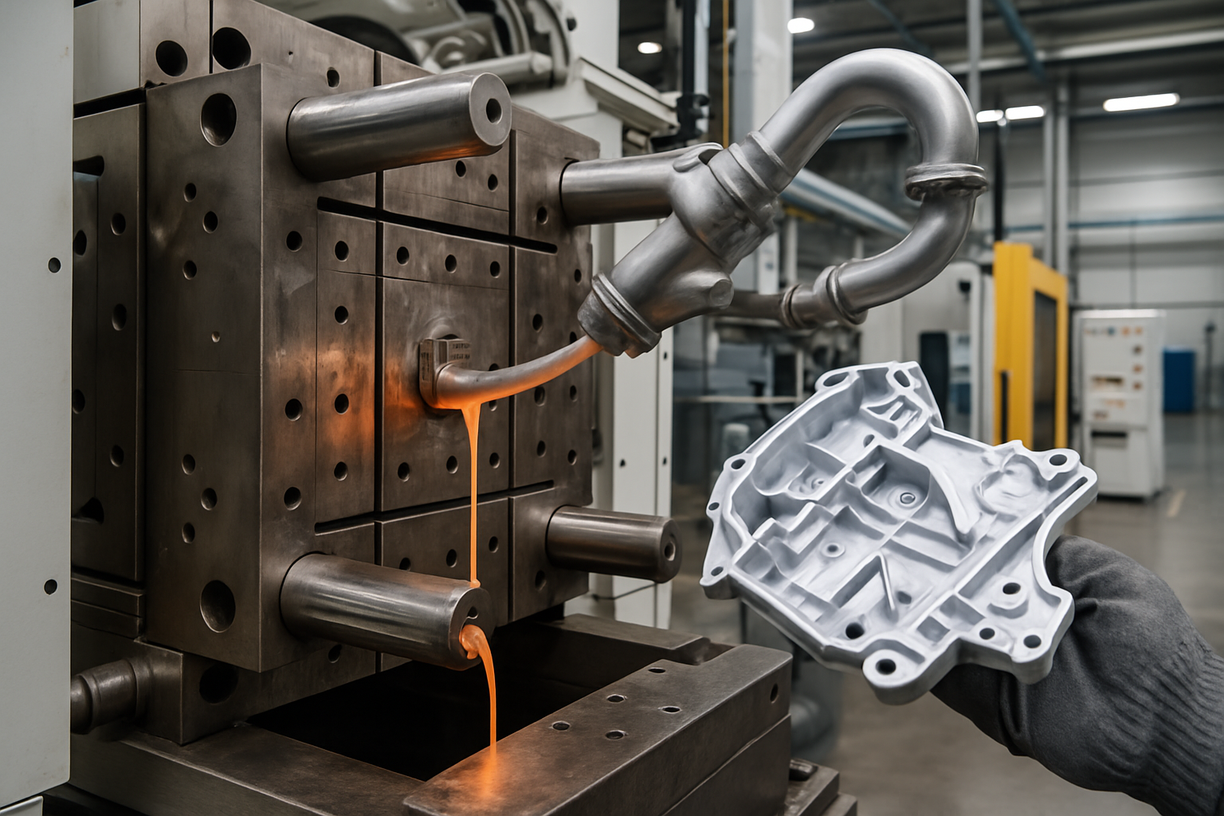

What is metal Casting? Basic understanding

Metal casting is a manufacturing process that involves pouring molten metal into a mold to create specific shapes as it cools and solidifies, enabling the production of complex and robust components. This process involves melting metal and pouring it into a precision mold, where it cools and solidifies into the desired shape, allowing for the creation of intricate and durable parts. Metal casting is ideal for large-scale production, offering high strength and cost-efficiency for automotive parts, machinery components, industrial equipment, and energy applications.

Choosing the right casting process: tailor-made solutions for optimal performance

The selection of the most appropriate casting method is essential to achieve a perfect balance of cost-efficiency, product integrity, and manufacturing reliability. At Prime, we don't believe in one-size-fits-all solutions. Our engineering team will carefully assess the unique requirements of your project to recommend and apply the most suitable casting techniques. Here is an overview of the key processes we offer:

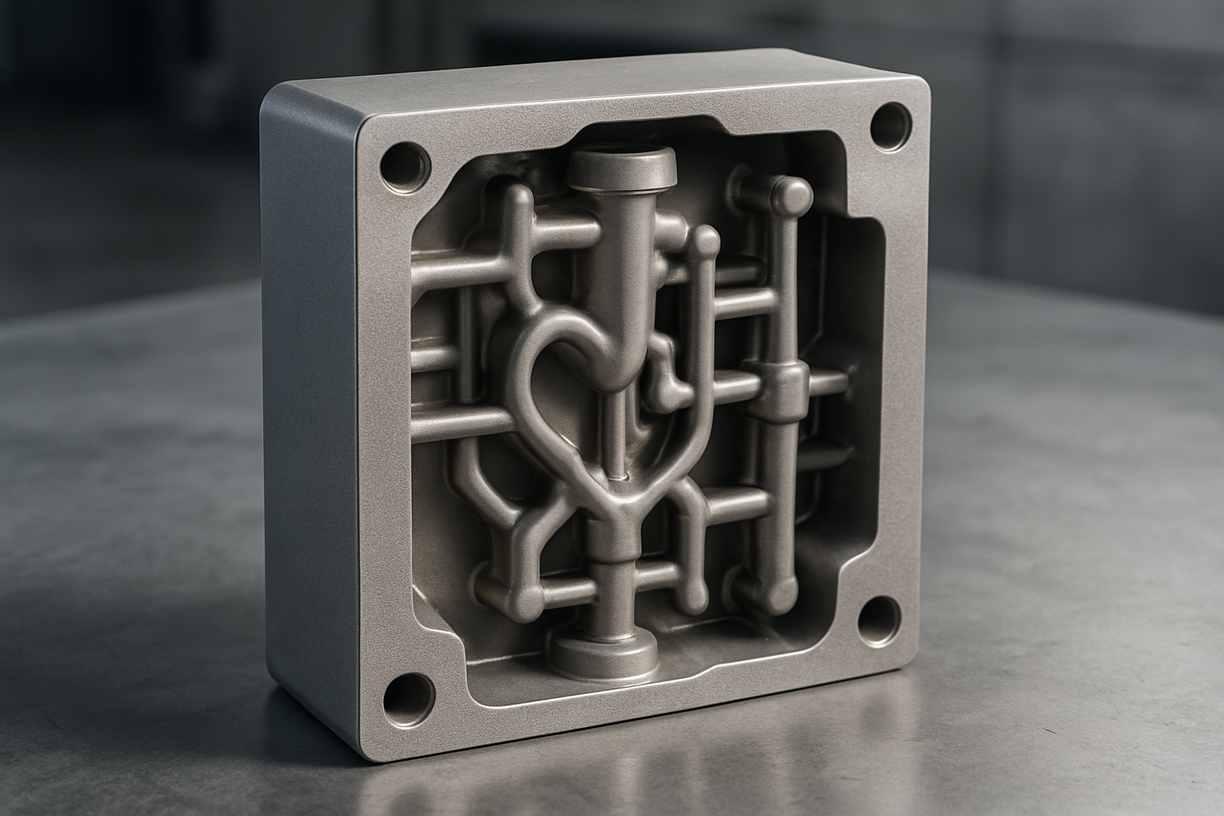

1. Precision casting: a sharp tool for forming complex structures

Precision casting (also known as lost wax casting) is the preferred process to realize the integrated molding of complex parts, which is suitable for the application scenarios with high structural details such as aviation accessories, valve parts and medical instruments. In this process, the wax pattern is used to copy the shape, and then the coated ceramic shell is fired and injected with molten metal, so as to obtain the finished product with high dimensional accuracy and excellent surface quality.

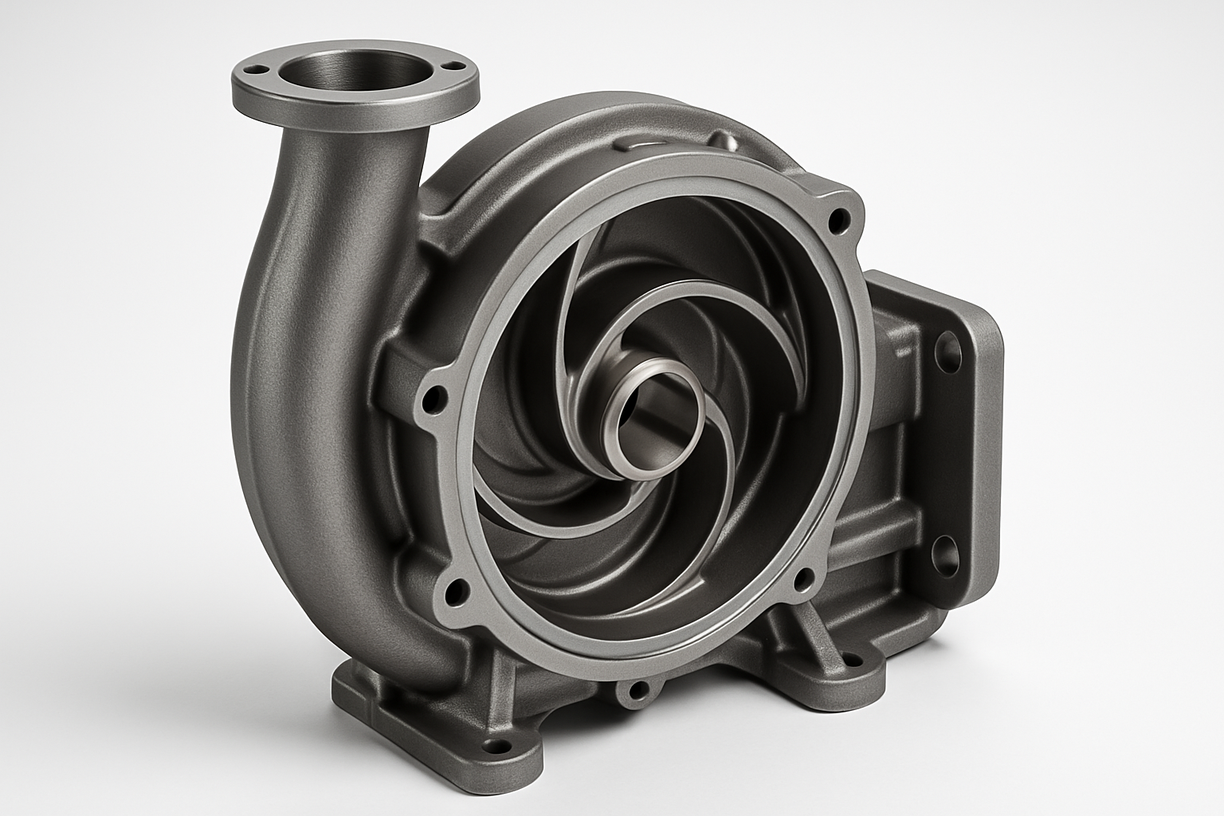

2. Sand casting: a solid foundation for heavy-duty construction

Sand casting is a classic process for manufacturing large, thick-walled or complex parts, which is widely used in pump casings, machine tool bases, valve bodies and engineering machinery. It can be used for cast iron, carbon steel, stainless steel and other metal materials, and the mold production cycle is short and the cost is relatively low.

3. Die casting: an efficient choice for light alloy components

Die casting is a high-pressure and high-speed process of injecting molten metal into metal molds, which is suitable for high-precision and high-capacity aluminum and zinc alloy parts, such as lightweight components such as automobile shells, motor end caps, and radiators. The molding cycle is short, the surface is smooth, the post-processing capacity is small, is the ideal choice for batch manufacturing.

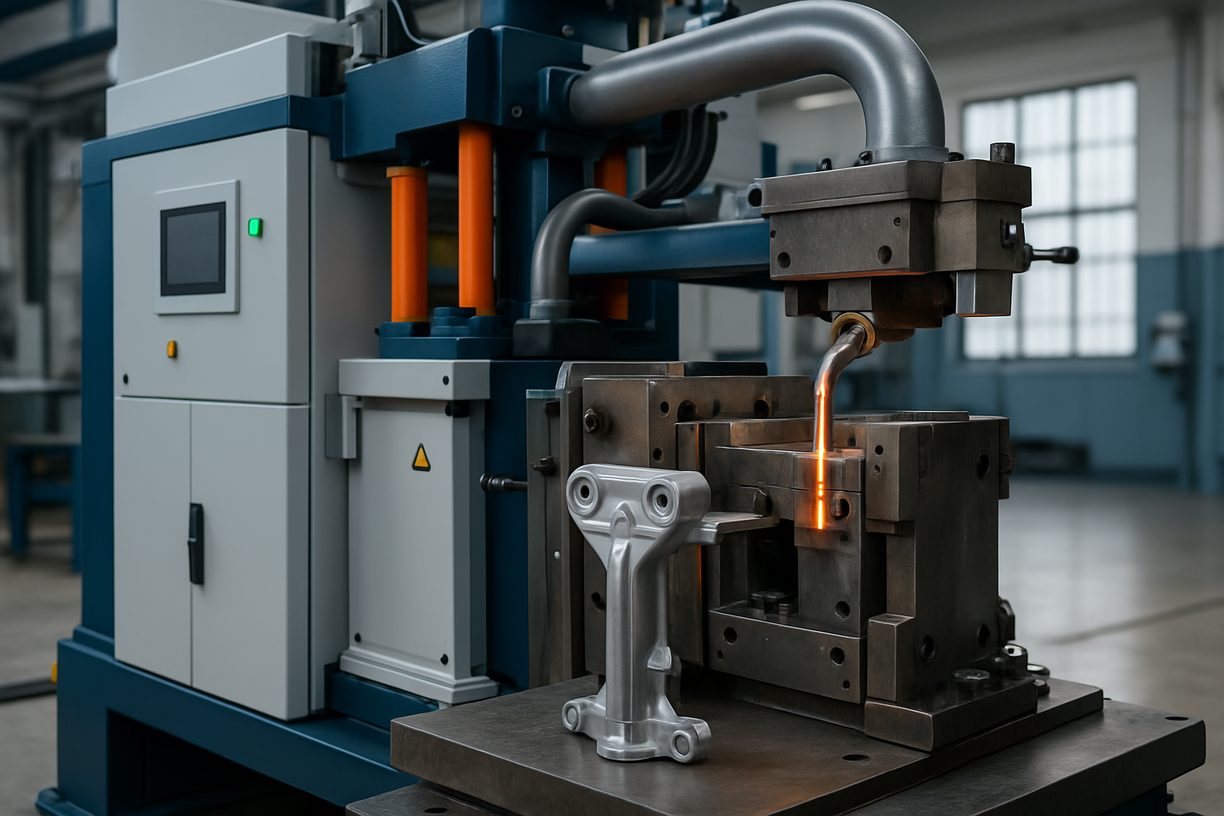

4. Low-pressure casting: a stable solution for precision aluminum parts

In low pressure casting, the molten metal is smoothly injected into the mold by air pressure in a closed furnace, which has the advantages of controllable forming process, low porosity and dense structure. It is especially suitable for aluminum alloy parts with high quality stability, such as automobile wheel hub, cylinder head, compressor shell, etc. .

Expert advice for curious buyers

To ensure that we recommend the most cost-effective and efficient process for your project, we encourage you to share your annual production forecast and key tolerance requirements early in the consulting phase. This advance information allows us to fine-tune our solution to your needs, optimizing performance and budget.

Ⅲ:Material Selection Guide: The Foundation of Performance

he selection of suitable materials is a crucial decision, which directly affects the performance, cost and process suitability of castings. At Prime, we provide professional guidance to assist you in this complex process and ensure that the material selection is precisely matched to your application needs. We evaluate a wide variety of metal materials, balance their properties, achieve the best results for the project, and help you address key challenges such as traceability and compliance.

Common Metal Materials and Their Properties

| Material | Corrosion Resistance | Cost | Strength (MPa) | Typical Applications |

|---|---|---|---|---|

| Aluminum Alloy | Excellent | Moderate | 150–400 | Automotive parts, Aerospace components |

| Stainless Steel | Excellent | High | 500–1000 | Food equipment, Medical devices, Marine parts |

| Carbon Steel | Poor to Moderate | Low | 250–600 | Machinery parts, Structural components |

| Gray Iron | Moderate | Low | 150–300 | Engine blocks, Pump housings, Machinery bases |

| Ductile Iron | Good | Moderate | 400–700 | Pipes, Gears, Automotive suspension parts |

| Brass | Good | High | 200–500 | Plumbing fittings, Decorative components |

| Zinc Alloy | Moderate | Low | 150–400 | Die-cast housings, Hardware components |

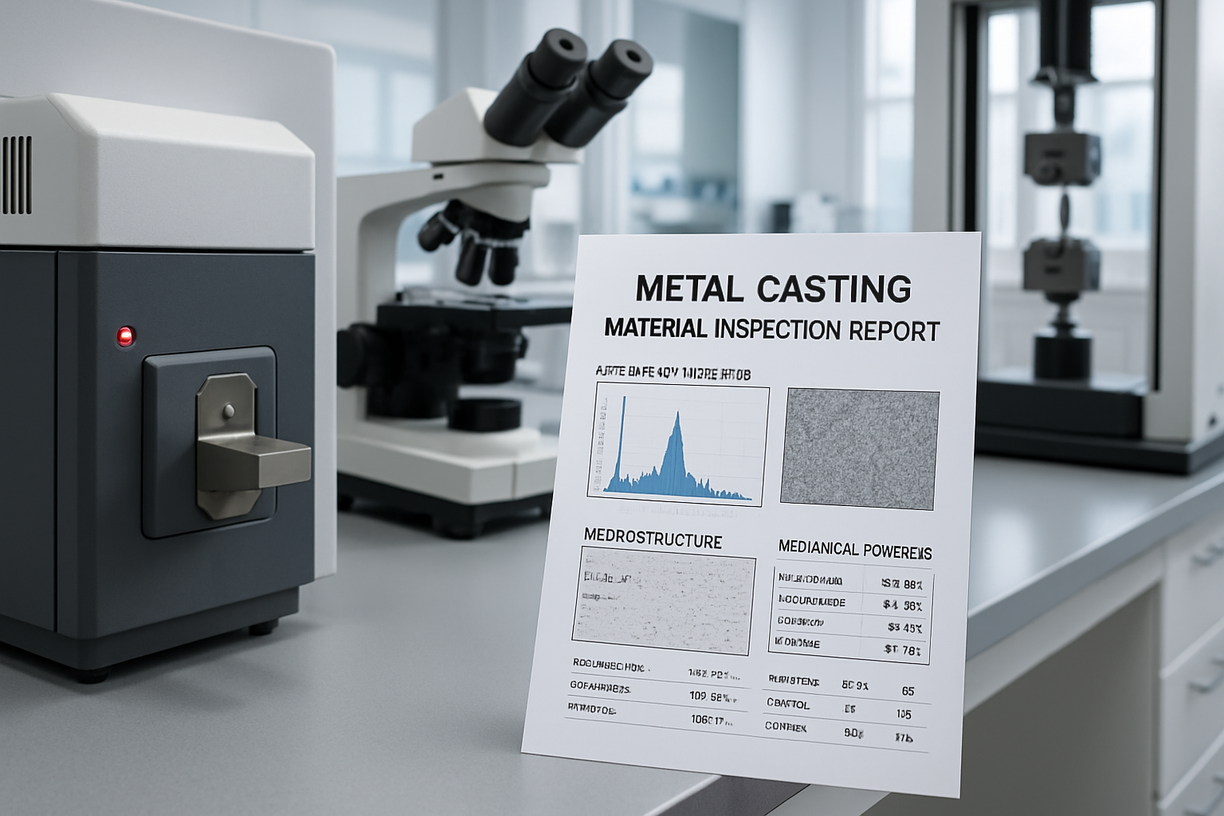

How PRIME Helps You Make the Right Material Choice

Our support goes beyond just providing a list of materials. We offer a suite of services to ensure your selection is not only smart but optimized to your specific needs — directly addressing traceability and compliance challenges:

Material Test Reports (MTR) & Analysis

We provide detailed chemical and mechanical analysis for every batch of material we source. This ensures full traceability and verifies that all specifications and quality standards are met — giving you complete confidence in your parts’ integrity.

Design for Manufacturability (DFM) Support

Our engineering team offers expert advice on dimensional adjustments and material performance to improve formability, reduce scrap rates, and enhance overall manufacturing efficiency. This proactive approach saves time and cost by optimizing your production design.

Total Cost of Ownership (TCO) Analysis

We perform parallel cost modeling that goes beyond material price alone. Our TCO analysis includes scrap rates, processing costs, and downstream assembly labor — giving you a complete picture of total project cost and helping eliminate hidden expenses.

Ⅳ:Surface Treatment Options: Enhance Durability and Aesthetics

Surface treatment is very important to improve the functional properties and appearance of castings. Prime offers a variety of customized processing solutions, each of which has been precisely designed to meet the standards and application requirements of different industries. With a wealth of professional experience, we ensure that your castings not only have excellent appearance, but also in the actual working conditions to achieve reliable and lasting performance.

- Sandblast shot blasting: Deburring, Surface roughness, adhesion.

- lectroplating (nickel, zinc, chromium, etc.): Improve corrosion resistance, aesthetics.

- Powder coating: Anti-corrosion, anti-rust, color diversity.

- Anodizing (applicable to aluminum) : Enhance hardness, corrosion resistance, decorative strong.

- Painting/Spray Painting: Combination of protection and decoration, strong adaptability.

- Heat treatment: Improve strength, hardness and wear resistance.

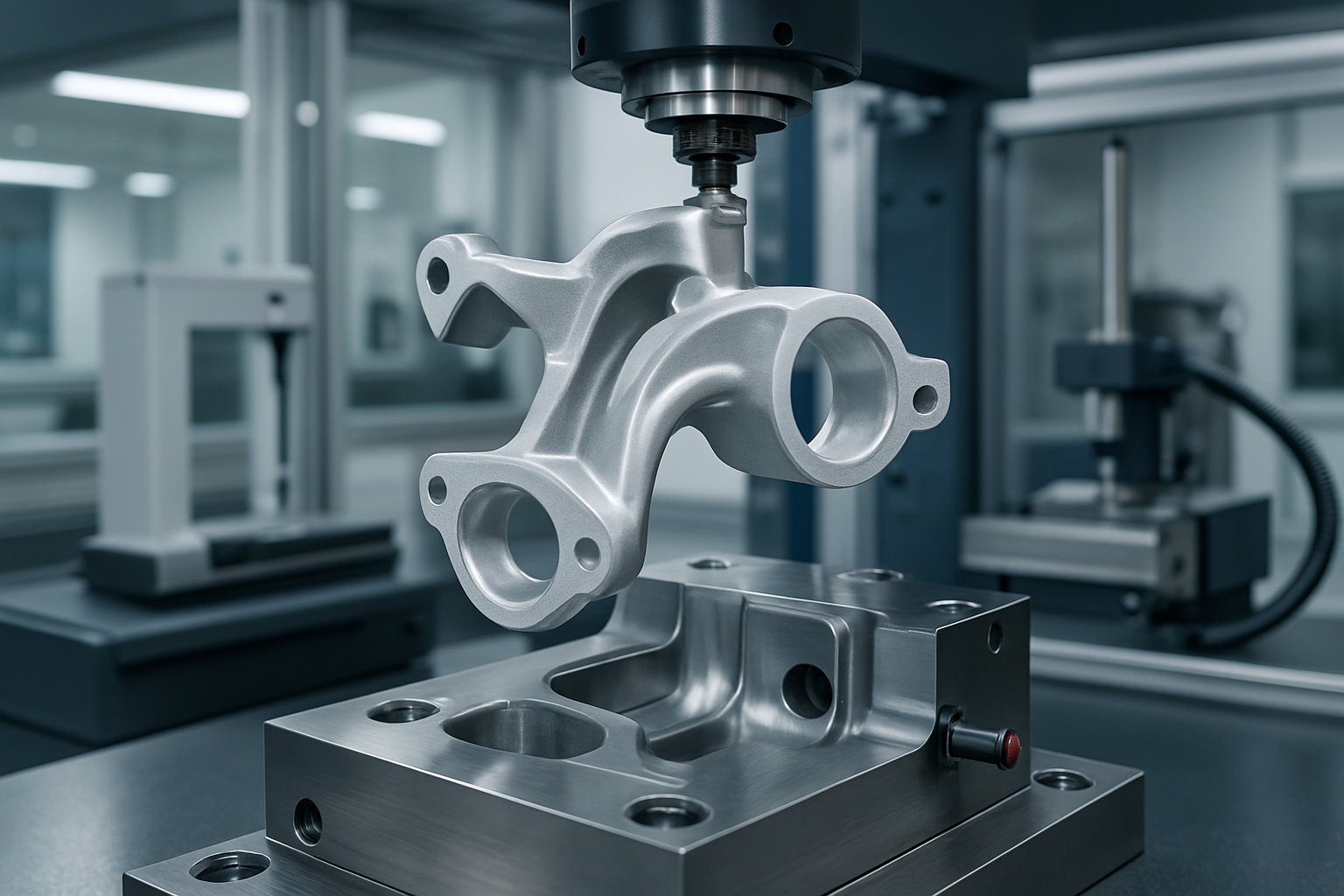

Ⅴ:Precision mould manufacturing: A key step to determine the quality of casting

In the process of metal casting, the dimensional accuracy, surface quality and production efficiency of the final product are directly determined by the accuracy and design quality of the mold. Prime has an experienced tooling engineering team dedicated to tailoring high-performance tooling solutions to each project.

We use advanced CAD CAM design software and CNC machining equipment to ensure that every step of the mold from design to machining meets strict quality standards. Whether for sand casting, gravity casting or die casting process, we can provide high durability, high repeatability precision mold, to meet the mass production of consistency and cost control of the dual requirements.

By optimizing the mold structure, we help our customers shorten the development cycle, improve the quality of castings and reduce subsequent processing costs, providing a reliable and efficient manufacturing base for global industrial buyers.

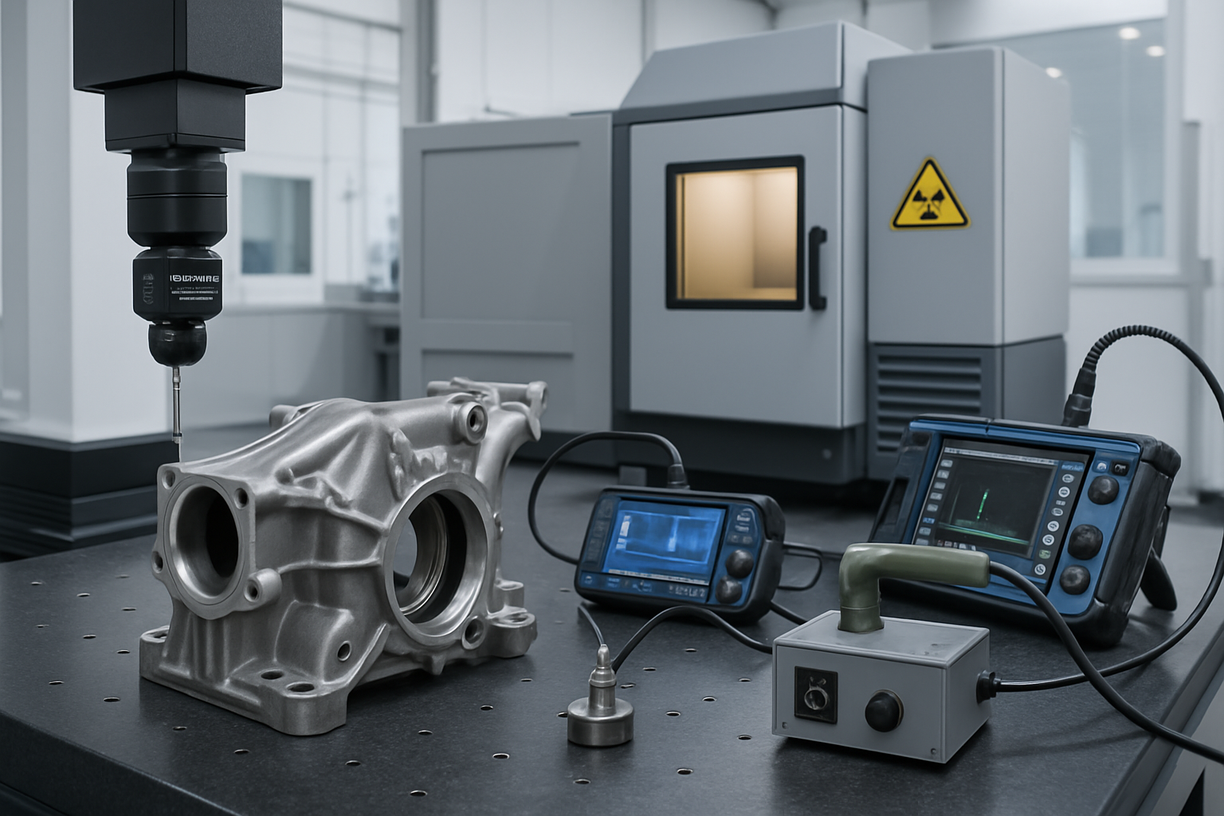

Ⅵ:Our Commitment to Quality

At PRIME, quality is integrated into every phase—not just final inspection. Our robust QA system ensures every part meets the highest precision and durability standards, addressing inconsistencies at the source.

- Incoming Material Inspection: Heat tracking and MTR reviews to verify chemistry and mechanical specs before production.

- In-Process SPC: Automated data capture and control charts with alarms for deviations in press force, cycle time, etc.

- 100% Online Visual Inspection: Inline cameras identify burrs, defects, or blemishes in real-time during production.

- Final CMM Validation: Every shipment undergoes dimensional confirmation using advanced coordinate measuring machines.

- Certificate of Conformance (COC): Each batch includes a detailed COC verifying materials, process, and inspection for full traceability.

Ⅶ:Common Casting Defects & PRIME’s Prevention Strategy

Metal casting is a complex process that, if not tightly controlled, can lead to costly defects. At PRIME, we proactively prevent these issues through advanced tooling, strict process control, and real-time quality monitoring.

1. Blowholes appear in the casting

Description: Gas Hole is usually in the process of liquid metal cooling, due to poor exhaust or gas content is too high, resulting in gas trapped in the casting or surface, the formation of voids. This will seriously affect the strength and density of the casting.

PRIME Solution: By optimizing the exhaust system of the mold, controlling the pouring speed of the liquid metal, and adopting a strict smelting degassing process, the gas content is effectively reduced, and the formation of pores is prevented from the source.

2. Shrinkage cavity or porosity in castings

Description: In the thick wall area of the casting, due to the uneven solidification rate or the unreasonable feeding design, it is easy to form internal depression or insufficient density, which affects the structural strength and subsequent processing stability.

PRIME Solution: We use professional casting simulation tools for feeding analysis, optimization of riser and cooling system design, to ensure the smooth solidification of liquid metal filling, eliminate shrinkage and porosity.

3. How do cold shuts form?

Description: Cold shut is due to the low temperature or poor liquidity of the liquid metal, resulting in multiple strands of liquid metal in the mold failed to fully integrate, forming obvious seams or clamp lines, affecting the appearance and air tightness.

PRIME Solution: We strictly control the pouring temperature, improve the fluidity of the alloy, and optimize the design of the flow channel system of the mold to ensure the smooth filling of the molten metal and prevent cold shut.

4. Inclusion in the casting

Description: Slag inclusion usually comes from slag, oxide scale and other non-metallic impurities mixed into the liquid metal and deposited in the castings, resulting in material performance degradation and internal defects.

PRIME Solution: We use high-efficiency smelting technology and ceramic filter system to ensure the purity of molten metal, and control the flow rate and direction in the pouring process to prevent slag from entering the mold.

5. Surface oxide inclusions appear in the castings

Description: When the molten metal reacts with the air to form an oxide layer, which can not be separated in time, grayish-black spots or flaky inclusions will be left on the surface of the casting.

PRIME Solution: We reduce the formation of oxide layer by introducing protective atmosphere or covering agent in the melting and pouring process, and improve the gate design to reduce the contact area between liquid metal and air.

Ⅷ:Diverse applications: the impact of PRIME casting components

Metal castings are indispensable parts in all walks of life. Their precision, cost-efficiency, and high scalability make them ideal for global manufacturing. At PRIME, we deliver tailored solutions that meet sector-specific technical standards and production demands.

1. The auto industry

Impact: The automotive industry is extremely demanding in terms of structural strength and durability, with castings playing a key role in the engine, transmission and chassis.

PRIME’s Role: We provide automotive-grade precision castings for engine housings, brake system components, steering system housings, etc. to ensure both safety and performance.

2. Industrial equipment

Impact: Industrial equipment needs to withstand long-term high-load operation, on the strength and stability of castings demanding.

PRIME’s Role: Our high-strength cast parts are used in a wide range of industrial machines, such as pump bodies, valves, gearboxes and machine tool bases, helping customers improve equipment life and reduce maintenance costs.

3. The power and energy industry

Impact: The energy industry has very high requirements for high temperature resistance, corrosion resistance and sealing performance of components.

PRIME’s Role: We provide castings for power equipment and energy systems, including turbine housings, generator housings, and wind equipment structures, to support the long-term stability of the energy system.

4. Agriculture and construction machinery industry

Impact: Harsh working environment, the components of the impact resistance, anti-wear capacity requirements.

PRIME’s Role: We provide durable castings for tractors, harvesters, excavators, and other equipment, such as connecting arms, housings, and axle parts, to meet reliable requirements under heavy-duty conditions.

5. Building hardware and utilities

Impact: Construction and infrastructure projects require high-volume, structurally stable, weather-resistant metal components.

PRIME’s Role: We provide precision castings for architectural hardware and urban facilities, such as manhole covers, balustrade bases, decorative components, etc. , taking into account both functionality and visual aesthetics.

6. Rail and heavy transport

Impact: High-speed operation and heavy-duty transportation pose great challenges to the structural strength, fatigue life and safety reliability of metal components.

PRIME’s Role: We provide high strength castings for rail vehicles and heavy transport equipment, such as axle brackets, brake system housings, connection structures, etc. , to ensure stable operation and safety compliance.

Whether you're in aerospace, consumer electronics, or construction — PRIME offers scalable, accurate, and cost-efficient metal casting tailored to your needs.

Not listed above? Our engineers will gladly assess your drawings and create a customized solution for your unique industry.

Discuss Your ApplicationⅨ:How to Choose the Right Casting Parts Supplier

Choosing the ideal casting parts supplier is a critical business decision that directly influences product reliability, production efficiency, and overall profitability. This guide outlines key evaluation criteria beyond just price—ensuring your supplier becomes a long-term strategic partner, not a source of delays, defects, or hidden risks.

1. Ability of quality control

High-quality castings must meet the structural accuracy, mechanical properties and surface requirements. Please make sure that the supplier has a complete quality system (such as ISO 9001, IATF 16949) , and equipped with coordinate, spectrometer and other inspection equipment.

- Prime Tip: Priority will be given to manufacturers with independent mold manufacturing and full-process inspection capabilities.

2. Level of process and equipment

Different casting requirements (such as sand casting, gravity casting, die casting, etc.) have different requirements for the process. Good suppliers should have a variety of process configurations and modern equipment to support custom development and mass production.

- Prime tip: Understand whether the supplier has CNC finishing, heat treatment, surface treatment and other integrated capabilities.

3. Material selection and technical support

Different applications have different requirements for material properties. Whether the supplier can provide professional material selection suggestions, alloy customization, and performance analysis is an important dimension to judge its strength.

- Prime tip: It is more comfortable to cooperate with the manufacturer who has the engineering team and can provide the material report and sample verification.

4. Delivery capacity and punctuality

Late delivery can lead to delays in the overall project schedule or missed sales season. Whether the supplier has a stable production scheduling system, inventory control and logistics management capabilities, directly related to supply security.

- Prime tip: Evaluate its average delivery time and emergency response mechanism for the past year to see if it can flexibly respond to order fluctuations.

5. Price and cost performance

Price is important, but the lower the better. The overall purchasing cost should be determined by taking into account factors such as product life, defective rate and The Adjuster.

- Prime tip:Choosing suppliers who strike a balance between“Price-quality-service” is more profitable in the long run.

6. Customer cases and market word of mouth

Suppliers with hands-on delivery experience and industry application cases tend to better understand buyers' needs and standards. You can also learn about their service performance through third-party platforms or customer reviews.

- Prime tip:Priority will be given to export-experienced, long-term service in Europe, the United States and the Middle East market mature factory.

If you are looking for a long-term cooperation foundry, Welcome to contact us for free technical advice and sample evaluation.

Ⅹ:Esign for Manufacturability (DFM)

Optimize your casting parts for production and cost with our collaborative engineering approach.

What is DFM? Design for Manufacturability (DFM) is a proactive engineering approach that simplifies designs, reduces costs, and improves quality by addressing manufacturability early in the design cycle.

At Prime, our DFM service becomes an extension of your engineering team, ensuring your casting parts are not just manufacturable — but manufacturable with excellence and cost-efficiency.

Buyer's pain:“My design is complex. I'm concerned about high production costs, potential manufacturing issues, and long lead times. How can I ensure my parts are optimized for casting?”

1. Early Involvement & Collaborative Review

Our engineers review your 2D/3D CAD models and specifications to identify manufacturability challenges and offer actionable improvements. Avoid costly redesigns and tool modifications later.

2. Material Optimization & Cost Reduction

- Size Reduction: Suggestions to reduce material use without compromising function.

- Material Type Recommendations: Based on strength, corrosion resistance, and cost.

- Scrap Reduction: Nesting and layout strategies to minimize waste.

3. Process Simplification & Efficiency

- Feature Simplification: Redesigning difficult features for easier tooling.

- Tooling Longevity: Designs that extend die lifespan and reduce downtime.

- Eliminating Secondary Ops: Using progressive dies to reduce welds, trims, etc.

4. Tolerance Control & Quality Improvement

- Critical Dimension Focus: Precision where it matters most.

- Springback Compensation: Simulation-backed corrections in tooling.

- Defect Prevention: Avoid wrinkles, cracks, burrs before they happen.

Our DFM service is not an extra cost — it's an investment in your project’s success. Leverage decades of manufacturing expertise by collaborating early with our engineers. Your casting designs will be built for peak performance, maximum cost-efficiency, and seamless production.

Minimize risk. Accelerate time-to-market. Gain a competitive edge.

Ⅺ:Metal Casting vs. CNC Machining: Choosing the Right Manufacturing Process

When sourcing metal parts, B2B buyers often face a critical decision: metal casting or CNC machining? Both are efficient manufacturing methods, but they shine in different applications. At PRIME, we provide both casting and machining services—offering impartial guidance and tailored solutions based on your specific project requirements.

Metal Casting: Ideal for High-Volume and Complex Shapes

Metal casting involves pouring molten metal into a mold, allowing it to cool and solidify into the desired form. It’s a cost-effective method for mass-producing parts, especially those with intricate geometries.

- Cost efficiency at scale: After the initial mold is created, unit costs drop significantly—ideal for large production runs.

- Complex geometry: Enables production of parts with internal cavities and intricate outer contours.

- Material savings: Near-net shaping reduces material waste compared to subtractive processes.

- Consistency: Fixed molds ensure repeatable quality for high-volume manufacturing.

- Wide size range: Castings can range from a few grams to several tons in size.

Best Applications:

Engine blocks, valve bodies, turbine blades, electronic housings, large structural parts for energy and industrial sectors.

CNC Machining: Ideal for Low Volume and High Precision

CNC machining is a subtractive process that removes material from solid blocks to create precise parts. It delivers exceptional accuracy and is suitable for small batches or parts requiring tight tolerances.

- Extreme precision: Supports tight tolerances and intricate 3D features not feasible in casting.

- Material versatility: Works with hard metals, plastics, and thick stock with no casting limitations.

- Low-volume adaptability: No need for molds makes it economical for custom and prototype runs.

- Design flexibility: Easily implement design changes via software, no tool modifications required.

- Superior surface finish: Machined parts typically require minimal post-processing.

Best Applications:

Aerospace components, precision medical implants, custom machine parts, complex prototypes, and parts with internal threads or fine details.

Comparison Table: Casting vs. CNC Machining

| Feature | Metal Casting | CNC Machining |

|---|---|---|

| Production Volume | High to very high | Low to medium |

| Part Complexity | Complex internal & external shapes | Complex 3D with high detail |

| Tooling Cost | High (mold cost) | Low (software programming) |

| Unit Cost | Very low (for high volume) | Higher per piece |

| Lead Time | Longer (mold setup) | Shorter (programming) |

| Material Waste | Minimal | Higher (material removal) |

| Tolerance | ±0.05mm typical | ±0.005mm possible |

PRIME’s Integrated Approach

PRIME offers more than just one solution. With deep expertise in both metal casting and CNC machining, we objectively evaluate your needs and recommend the most cost-effective and technically appropriate method.

Share your part design, material specs, volume expectations, and timeline—and our engineering team will help you make the smartest manufacturing choice.

Ⅻ:Global Supply Chain & Logistics: Seamless Worldwide Delivery

For international B2B buyers, efficient and reliable logistics are just as important as product quality. With rich global trade experience and a robust supply chain network, Prime ensures your precision casting parts are delivered seamlessly, on time, and within budget — wherever you are.

Buyer Concern

“How can I ensure my parts arrive on time without unexpected customs delays or hidden costs when working with international suppliers?”

Prime’s End-to-End Logistics Solution

Prime's commitment goes far beyond manufacturing. We provide intelligent logistics and supply chain support to eliminate sourcing friction and boost your global competitiveness. Here’s how we deliver peace of mind and precise parts — anywhere on the map.

1. Trade Compliance & Export Expertise

- HS Code Classification: Ensures correct tariff application and minimizes customs delays.

- Comprehensive Documentation: Including invoice, packing list, certificate of origin, and destination-specific forms.

- Up-to-date Compliance: We track evolving export laws and sanctions so your delivery stays uninterrupted.

2. Flexible Transport Strategies

Our global logistics partnerships ensure optimal routing:

- Air Freight: Fast, secure delivery for urgent and high-value orders.

- Ocean Freight (FCL/LCL): Best for bulk and cost-efficiency.

- Multimodal Options: Blending speed and budget using air-sea-land combinations.

3. Real-Time Tracking & Proactive Communication

Transparency is key. From factory to your doorstep, you’ll get real-time updates. We alert you to potential delays before they become issues.

4. Secure Packaging & Damage Control

- Custom-Fit Packaging: Designed for secure transit.

- VCI & Anti-Corrosion Materials: Protects precision metal components during storage and shipment.

- Impact Absorption: Prevents transit damage with protective cushioning.

5. Global Warehousing & Inventory Buffering

For recurring buyers and long-term contracts, we offer regional warehousing and JIT inventory options — reduce lead times, smooth out supply fluctuations, and ensure business continuity.

The Prime Logistics Advantage

Let Prime handle logistics, compliance, and delivery while you focus on growth. We bring your components where you need them — on time, every time.

XIII: PRIME R&D and Innovation — Advancing Metal Casting Technology

In a rapidly evolving industrial environment, sustained innovation is key to staying ahead. For B2B buyers, choosing a supplier that invests in R&D ensures access to advanced solutions, enhanced material performance, and a long-term competitive edge. At PRIME, our dedication to research and development focuses on pushing the boundaries of metal casting technology to deliver measurable value.

Buyer Concern: How does this supplier stay at the forefront of technology? Can they support my future development goals and adapt to shifting technical demands?

1. Advanced Material Research

We actively study and test new alloys and composites to broaden our casting capabilities. This includes lightweight, high-strength materials for aerospace and automotive applications, as well as specialized materials for high-temperature and corrosive environments. Our materials team works closely with leading institutions to ensure we can cast the materials of the future with confidence and precision.

2. Process Optimization & Automation

Our R&D is centered on optimizing casting processes for greater efficiency, accuracy, and cost-effectiveness through:

- Smart Mold Development: Integrating sensors and real-time monitoring to extend mold life and reduce downtime.

- Robotics + AI: Automating material handling, part transfer, and inspections to improve precision and reduce labor costs.

- Simulation & Predictive Modeling: Using advanced software like FEA/CFD to prevent defects before production starts.

3. Sustainable Manufacturing

We’re committed to minimizing environmental impact and supporting our customers' sustainability goals. Our initiatives include:

- Energy Efficiency: Investing in energy-saving equipment and layout improvements.

- Waste Reduction & Recycling: Maximizing scrap recovery and reducing process waste.

- Eco-Friendly Coatings: Researching lubricants and surface treatments that reduce harmful emissions and chemical use.

4. Tailored Casting Solutions

Our R&D capabilities enable us to engineer highly customized casting solutions for complex and unique requirements. Whether your project involves novel methods, exotic materials, or critical tolerances, our engineers work alongside your team from concept to production—turning challenges into real-world results.

The PRIME Innovation Advantage

Partner with PRIME and gain a forward-thinking casting manufacturer that continually invests in future-ready technologies. From materials to processes and quality systems, our innovation ensures your products benefit from the latest advancements—delivering long-term performance and sustainable value.

Learn MoreXIV: Value-Added Services — Beyond Casting, Toward Complete Solutions

For B2B buyers, simplifying the supply chain and reducing vendor count can drive significant cost savings, improve efficiency, and minimize complexity. At PRIME, we provide a full suite of value-added services that turn your casting needs into a complete one-stop sourcing solution—reducing management overhead and delivering parts ready for integration.

Buyer Concern

"I need more than just a casting—what about machining, assembly, or surface treatment? Managing multiple vendors for different steps is time-consuming and increases quality risks. Can one supplier do it all?"

PRIME’s Integrated Solution

As your single point of contact across manufacturing and post-processing steps, PRIME ensures seamless transitions and consistent quality control. Our integrated services deliver fully finished parts—saving you time, cost, and coordination efforts.

1. Secondary Machining Operations

- CNC Machining: For ultra-tight tolerances, threads, complex bores, and 3D profiles that casting alone can’t achieve.

- Tapping & Reaming: Precision internal threading and hole refinement for fit-critical applications.

- Grinding: Flatness control and thickness accuracy for high-performance surfaces.

2. Assembly & Subassembly

We deliver components pre-assembled to fit directly into your production line:

- Mechanical Assembly: Combining castings with springs, inserts, fasteners, or plastic components.

- Welding: MIG, TIG, and spot welding for strong, permanent joints.

- Fastener Insertion: Manual or automated embedding of studs, nuts, and threaded elements.

3. Kitting & Custom Packaging

- Kitting: Consolidating related parts into ready-to-assemble kits tailored to your line-side needs.

- Custom Packaging: Designed to protect fragile components and optimize shipping space.

- Labeling & Barcoding: Clear identification and inventory integration through custom labeling systems.

4. Heat Treatment

- Annealing: Relieves internal stress and enhances ductility before forming or machining.

- Hardening & Tempering: Improves wear resistance, strength, and durability of functional components.

5. Cleaning & Deburring

- Precision Cleaning: Removes oils and contaminants to ensure parts are ready for downstream processes or end use.

- Advanced Deburring: Eliminates sharp edges via tumbling, laser deburring, and vibratory polishing for safety and fit.

The PRIME One-Stop Advantage

By consolidating value-added processes with PRIME, you reduce lead times, minimize inter-supplier quality risks, and lower your total cost of ownership.

Our seamless, vertically integrated workflow goes far beyond casting—making us a true manufacturing partner in your product’s success.

Materials

| Gray cast iron | Carbon Steel |

| Ductile iron | Stainless steel |

| Alloy | Stainless steel precision castings |

| Aluminum die castings | Other Metals |

Finishing

| Machining | Deburring & Chamfering |

| Surface Finishing | Heat Treatment |

| Welding & Repair Welding | Grinding & Polishing |

| Inspection | Other ways |

XV:More information on custom metal castings

High-quality metal castings, designed to provide you with exclusive customization to meet your industry needs.

Production Method

- Sand mould casting

- Metal mould casting

- High pressure die casting

- Investment casting

- Centrifugal casting

- Lost-foam casting

In Summary

Choosing the right metal casting supplier is a strategic decision that goes far beyond unit pricing. In this comprehensive guide, we’ve covered the essentials of casting—from core processes and material selection to quality management and global logistics. The key to success lies in selecting a partner who not only meets your immediate requirements but also supports your long-term growth and innovation.

Key Takeaways for B2B Buyers

- Technical Excellence is Essential: Modern casting applications demand advanced tooling, process expertise, and the ability to deliver consistent quality—from sand casting to investment casting for complex geometries.

- Quality Cannot Be Compromised: In today's competitive market, defects are costly. Choose suppliers with robust QMS, certified processes, and full inspection protocols including SPC, IQC, and final QA.

- Think in Terms of Total Cost: True value includes tooling, quality risk, delivery reliability, and manufacturability support. A slightly higher unit price may yield much lower overall costs.

- Value Strategic Partnerships: Work with suppliers who act as partners—those who understand your goals, provide proactive engineering input, and care about your product's success beyond simply making castings.

- Global Reach, Local Responsiveness: A great partner combines global scalability with knowledge of customs, compliance, and logistics—ensuring reliable delivery and adaptable service wherever you operate.

Why PRIME Stands Out

At PRIME, we deliver what smart B2B buyers look for in a casting partner—30+ years of manufacturing experience, ISO 9001:2015 certification, and state-of-the-art equipment. But what truly sets us apart is our dedication to solving problems, accelerating development, and enabling your growth.

From DFM consulting and rapid prototyping to full-scale casting and global logistics, our integrated process ensures consistency, precision, and time-to-market excellence.

Global Capability, Local Touch

With 15 high-speed casting lines and established logistics channels across North America, Europe, the Middle East, and Australia, PRIME is equipped to scale with your business globally. Our logistics experts ensure smooth customs clearance, on-time shipping, and optimized packaging every time.

Discover how the right casting supplier can be your competitive advantage in achieving production efficiency and manufacturing excellence.

Your Next Step

Whether you’re sourcing casting parts for the first time or seeking to improve your current supply chain, we welcome you to experience the PRIME advantage. Upload your drawings and technical specs through our secure portal, and receive a full feasibility review and competitive quote within 24 hours.

Let’s build something extraordinary—together.

Get a Quote NowJust a Few of the Partners Who Trust Our Quality

*Logos are property of their respective owners.

What Our Customers Say

Real feedback from global buyers who trust us to deliver high-quality, customized industrial components.

Harry M., New York

Purchasing Manager – Metal Components

We’ve sourced CNC machined parts from Prime for over two years. The precision is consistently excellent, tolerances are spot on, and their team is responsive and professional. Fast lead times and secure packaging make them a reliable long-term partner.

Robert J., California

Strategic Sourcing Specialist – Industrial Hardware

The forged components we received from Prime were top quality — strong material integrity, accurate dimensions, and zero defects. Their team understood our specs clearly and delivered right on schedule. Great supplier for high-stress applications.

Emily T., Texas

Supply Chain Buyer – Custom Metal Parts

We ordered a batch of custom metal welded assemblies from Prime, and the quality was outstanding. The welds were clean, uniform, and met all our strength requirements. Communication was smooth, and delivery was faster than expected.

Hannah K., Ontario

Senior Buyer – Automotive

Prime supplies us with custom metal casting parts that meet strict automotive standards. Their ISO-certified quality, fast prototyping, and on-time delivery make them a trusted partner in our supply chain.

Luis R., Barcelona

Procurement Lead – Electronics

Prime has been a reliable partner for our custom plastic parts in consumer electronics. The injection-molded components are precise, durable, and always delivered on time, helping us stay competitive in the market.

Nadia P., Dubai

Category Manager – Industrial Projects

Prime delivers high-quality custom metal forgings for our industrial machinery. The parts are strong, reliable, and meet our exact specifications. With consistent quality and on-time delivery, Prime has become a trusted partner in our long-term projects.

Jon S., Munich

Operations Buyer – Machinery

Prime’s custom metal fasteners have proven to be durable and precise, perfectly fitting our heavy-duty machinery. Their consistent quality and reliable delivery help us maintain smooth production with fewer interruptions. Prime is a supplier we can count on for critical components.

Aisha M., Sydney

Sourcing Manager – Energy

From quoting to final inspection, Prime stayed on schedule with transparent updates. Their QC reports, salt spray results, and traceability made onboarding very smooth.

Get Your Custom Solution & Quote

REPLY WITHIN 24 HOURS

Start a Conversation with Our Experts

When you contact us, you get more than just a price. You get a dedicated partner.

- ✔ 30+ Years of Manufacturing Excellence, Direct from Our Factory

- ✔ Custom-Engineered Solutions for Your Needs

- ✔ Global Shipping & Logistics Support

- ✔ A Transparent, No-Obligation Quote

- ✔ 100% Confidentiality Guaranteed

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!